Explosions are sudden, localised, overpressure events. They result from a rapid increase in volume and energy upon ignition of a fuel with available oxygen, and the consequent release of heat, kinetic energy, and high-pressure gases.

Normal explosions erupt at a speed of up to 340 metres/1,120 feet per second, the speed of sound in dry air. This is what occurs in ordinary industrial or commercial atmospheric explosions and are the focus of ATEX legislation.

Explosions that occur faster than the speed of sound are referred to as detonations, and require manufactured or engineered tools, chemicals, and materials to occur. The energy of these events travels as shock waves through the medium, with less displacement of the medium itself.

These occur more commonly in mining operations because of the use of specific materials. This discussion is confined to ordinary explosions such as the ignition of atmospheric dust, gas, or vapour.

Risks per Industry

Some risks are obvious even to a casual observer, while some are invisible without some familiarity with the operation or processes involved. Certain industries require equipment suited for ATEX Zones. For example our ATEX Camera, which is suited for environments with a risk of gas explosions. Let’s consider some examples.

Obvious

- Chemical Industry

- Many chemical combinations are inherently explosive

- Powders, once airborne, also present a hazard

- Power Generation

- Coal dust is fuel

- Natural Gas is a fuel

- Woodworking Industry

- Fine sawdust is an excellent airborne fuel

- Biomass Plants

- Methane gas

- Wood dust during pelletising process

- Metal shops

- Many metals (e.g. Aluminium or aluminium mixtures) will oxidise rapidly and explosively

Hidden

- Food Industry

- Powdered sugar is a pure hydrocarbon

- Milled grains burn easily and energetically

- Waste Treatment Plants

- Fermented gases (e.g. methane) burn readily

- Chlorine gas combines with ammonia to be highly explosive

- Pharmaceuticals

- Cellulose and lactose are used as pill-fillers and are explosive as airborne dust/particulate

- Various alcohols are used for blending and formulations

- Landfill Sites

- Evolved gases (e.g. methane, hydrogen sulphide)

- Paint Shops

- Solvents as mist can form explosive atmospheres

- Paints (metallic or organic) can be fuel

Gas Dangers

Gas explosions can cause immense damage because vapours or gases can insinuate themselves into cracks and crevices, move between rooms, and are often invisible. Until they meet a source of ignition, people may not even be aware of their presence.

Some are odourless, too, such as methane, which is why we add gases like hydrogen sulphide or methyl mercaptan (aka methanethiol) to alert people to leaks of natural gas, or before that, of coal gas. Those flammable additives are easily detected by the human nose, even in miniscule quantities.

Gases ignite very easily, say, by just a static electric spark. Something as ordinary as the connection arc of a light switch can set off a gas explosion. Someone lighting a match or turning on a gas range with an auto igniter for the gas could be the cause. A home explosion from a natural gas leak could be triggered by an old-fashioned house-phone ringing—their solenoids spark when they rapidly make and break the electrical connections to ring the physical bells inside.

Dust Dangers

Generally speaking, dust explosions are harder to ignite than gas. The fuel first has to be airborne, and then something hot enough to ignite a particle must exist. After it is started, it expands by a cascade effect where one burning particle supplies sufficient energy to ignite its neighbour.

Different size particles can represent different levels of threat, just as density per cubic volume can alter an explosion’s characteristics. Coarse sawdust is less dangerous than very fine sawdust in the same density/volume. Very fine sawdust has a massive surface area compared to its available energy. It can be consumed quite quickly releasing all of its energy at once. Large particles have more surface area and less fuel, so burn more slowly, and take more energy to reach a critical point.

Propagation

A dusty work environment with outside ventilation might be safe, but if several individual units share common ventilation, fire can propagate through that system from one unit to the next. This is why such ventilation connections require shutters that slam shut when there is an extreme pressure change on one side, preventing flames from passing to another area. The explosion can only vent outside of the building, not within different units.

Other Dusty Dangers

Dust accumulates around equipment such as coal conveyors, for example, or chutes and movement systems for flour, sugar, and other dusty products. These need regular maintenance and clean up so powders and dusts never reach dangerous levels. It may be benign just lying there, but a wind gust can turn it into an instant threat.

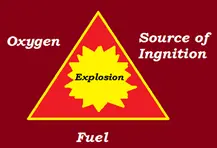

Explosion Elements

Oxygen is 20% of our atmosphere and thus hard to eliminate, so generally we work to limit the availability of fuel and the ignition source. Ignition causes could be a spark, open flame, or a heat source, like an electrical radiant heater. Fuel can be dust, gas, or vapour. If any one element of an explosion is absent, the explosion won’t occur.

Explosive Properties of Fuels

Fuels only react in certain ratios. For example, hydrogen will react (with atmosphere) at concentrations over 5%, but less than 95%. Some fuels have much more constrained limits. We call these limits the UEL and LEL, or Upper and Lower Explosion Limits, and they are expressed as percentages.

If you exceed the UEL, or fall short of the LEL, explosions cannot occur. Keep fuels outside of the limits and you are safe. Similarly, if you keep the temperature outside of the combustion range of the fuels, that is safe, too.

Injuries from Explosions

Injuries are not always apparent. Bleeding and physical trauma such as shrapnel are obvious. Symptoms such as deafness, breathing difficulty, shock, concussive, or deep tissue injuries may not show physical signs. All explosion victims are considered seriously injured until proven otherwise.

Serious burns can result from the extreme radiance of an explosion, too. Outward signs may not manifest for many minutes after exposure, but the pain is real.

The Takeaway

It is difficult to control the presence of oxygen. You must either control the temperature, keeping it below the point of combustion of the materials you are work with, or control the sources of ignition.

When fuel of any sort accumulates, it must be removed, physically in the case of dust and powder, or ventilated, in the case of gas or vapours. Don’t become a matter of historical record…

Be aware; be safe; keep it clean; and, most importantly, do your regular maintenance!

The Imperial Sugar Refinery dust explosion was the largest in U.S. history. It resulted in 14 deaths, dozens of injuries, and the complete and utter destruction of the more than one hundred year old facility.