What is ATEX?

ATEX stands for ATmosphère EXplosibles (from the French for Explosive Atmospheres). Formerly it combined two European Union (E.U.) Directives for defining environments where an atmospheric explosion hazard existed.

There were a confusingly large number of variants describing the two main directives for ATEX. With 27 countries in the E.U., there are a lot of opinions about what comprised proper nomenclature.

The older forms included Product Directive 94/9/EC, for equipment manufactured before 2016, which was also known as ATEX 95, ATEX 100a, or the ATEX Equipment Directive.

The second aspect, the protective feature for people and property was known as Operating Directive 1999/92/EC, or Directive 99/92/EC, ATEX 137, ATEX 118a, or the ATEX Workplace Directive.

The variations, subtle and gross, were too disparate and confusing. In February 2014, it was all harmonised by the European Parliament and the Council of the European Union under Directives for Equipment 2014/34/EU (aka ATEX 114) and for Health & Safety under ATEX 153.

Whatever name it arrived under, it required that any device, electrical or mechanical, shall not provide a source of ignition in an explosive atmosphere. They further specified that:

It is the duty of Member States to protect, on their territory, the health and safety of persons, especially workers, and, where appropriate, domestic animals and property, especially against the hazards resulting from the use of equipment and systems providing protection against potentially explosive atmospheres.

Ultimately this integration allows the free movement of ATEX goods anywhere in the E.U.—knowing that the same standards are upheld uniformly, everywhere—if the item bears the Ex symbol and has a certification.

What is ATEX Certification?

ATEX Approval Explained

ATEX Certification and ATEX Approval are precisely the same things, simply using different words. To eliminate confusion, pick your favourite and stick with it.

In the E.U., ATEX Approval is required for equipment that is to be used in potentially explosive atmospheres. Generally speaking, these hazardous areas are found in the oil & gas, pharmacy, and woodworking industries, but can occur virtually anywhere, when the processes and/or circumstances allow.

The basic principle of the certification is that any equipment used in potentially explosive atmospheres must not form a source of ignition, or pose a Health & Safety threat to workers, employees, or property. Such equipment must meet design specifications comparable to those set out in Directives ATEX 114 and ATEX 153.

ATEX Approval and ATEX Rated Products

ATEX Approval means that these products are suited to be used in explosive atmospheres, sometimes known as EX Zones. Products that are safe to be used in EX Zones are sometimes also referred to as ATEX approved or ATEX rated.

ATEX Types of Explosive Atmospheres

Simply put, ATEX Approval states that atmospheric explosion dangers, threats to life and health, and property damage, must be mitigated and/or minimised for workers, owners, and members of the general public.

Common sources of ignition in electrical equipment are sparks from making or breaking a circuit (e.g. a light switch), or the ordinary operation of a standard electric motor that uses brushes. Often, for example, if you look inside of the ventilation grate of a conventional electric drill when it is operating, you can see the fountain of sparks as the brushes continuously make and break contact to drive the motor, allowing it to turn. In an ATEX zone, these sparks could cause an explosion.

ATEX is further subcategorised into two discrete environments, two types of hazardous material, and three levels of risk. Let’s look at them now:

Environments

The two environments are above ground (typical), and below ground (mining). Both environments are regulated, but the latter category is much more stringently regulated due to the significantly higher level of risk for injury and damage beneath the Earth’s surface.

All explosions can cause both damage and fatalities. In a confined space, however, the severe overpressure of an explosion is concentrated, propagating much further because of the limited expansion room.

Materials

There are two vastly different classes of materials to consider:

- Flammable Gases, Mists, and Vapours

- Combustible Dusts

Flammable Gases, Mists, and Vapours exist in such industries as petrochemical processing, automotive painting, manufacturing pressurised propellants (industrial or household sprays), welding, and often, for home heating (e.g. Natural Gas).

Combustible Dusts occur in processing environments, such as lumber mills, food refining, grain storage, and coal mining. Referring to organics, it is said that anything which did not originate in “rock” can provide fuel for a dust explosion.

In point of fact, rapid immolation of dust is responsible for most of the spectacular explosions that you see in films. It provides a large visual effect (fireball rising), extinguishes quickly, and can be well-controlled in the proper circumstances.

In an enclosed structure, however, the flames can race quickly from one end of the building to the opposite end and from top to bottom, in just moments. Such was the case with the Imperial Sugar dust explosion, which generated such a huge overpressure explosion that it cost several lives and completely destroyed the sugar packaging plant.

Levels

Constant defines near continuous existence of airborne flammables, with only rare or occasional exceptions. Frequent means regular occurrences, such as part of a process, where some event permits its existence for some period of time. Rare identifies normal, everyday circumstances, where exceptional circumstances may arise.

In 1878, it only took a single spark to blow the solid concrete roof off of Washburn Flour Mill, sending remnants hundreds of feet in the air. That accident changed milling forever in North America. It destroyed the entire building, killed all 14 workers, knocked down two adjacent mills killed more workers there, and blocks of concrete and limestone rained down as far as eight blocks away from the site. We learned from these events.

Our own ATEX Camera is a good example of products that come with an ATEX certificate. It may therefore be used safely in specified hazardous areas.

What are the applicable ATEX directives?

As noted earlier, there were a number of names by which these variations were known, but that has all been consolidated under Directives for Equipment 2014/34/EU (aka ATEX 114) and for Health & Safety under ATEX 153. This creates consistency between all products sold (or imported into the E.U.) for use in potentially explosive atmospheres, anywhere in the E.U.

ATEX Certification Process

How to get ATEX Certification

ATEX certification requires product design to the standards as set out in the ATEX documents. Your engineers will likely perform their own testing, but eventually it will need to be investigated by designated engineers at an approved testing facility so that an official certificate can be issued.

Low level testing for conventional use can often be done on-premises by qualified engineers, and the CE marking can be obtained. More complex testing is required where threats are immediate, such as cyclic repeating of events subject to potentially explosive atmosphere risks.

An example might be a grain farmer using a conveyor or air-driven system to lift grain to the top of a silo. Since it is an inherently dusty task, sparks, whether from static electricity or electrical motors, have to be eliminated. In the confines of a concrete or steel silo, damage and life loss could be inevitable if things were to go awry.

Who provides ATEX Certification?

There are many familiar names providing certification. Intertek is familiar in Europe, as the amalgamation of a 19th century British marine surveying business, a Montreal Laboratory, and Thomas Edison’s Testing Lab.

Similarly the CSA, or Canadian Standards Association, was founded over a century ago to provide engineering standards in Canada. CSA is now a world renowned, non-governmental, independent group of engineers, and is a Notified Body for ATEX activities.

The British Scientific Instrument Research Association (BSIRA), later known just as SIRA, was founded at the same time, and was another Notified Body for ATEX. SIRA amalgamated with CSA in 2009 and still provides SIRA Certification Services (SCS) for ATEX.

The Deutscher Kraftfahrzeug-Ueberwachungsverein, (English: German Motor Vehicle Monitoring Association), or DEKRA is a Certifying Body (CB), too. Indeed, even the U.S. Underwriters Lab (UL) is an ATEX Notified Body. Clearly there is no shortage of expertise in this area from many respected testing organisations.

ATEX zone 2/22 certification

Zone “2” and Zone “22” indicate non-likely presence of explosive atmospheres. The two (2) rating indicates the lowest ordinary possibility of flammable gas. The twenty-two (22) rating indicates the lowest ordinary possibility of flammable dust. The Ordinary Location certification requires nothing more than the CE mark as a self-declaration representing that the equipment conforms to expectations for the product type.

ATEX zone 1/21 certification

Zone “1” and Zone “21” indicate the occasional presence of explosive atmospheres due to a process. Similar to the foregoing, the one (1) rating indicates the presence of flammable gas. The twenty-one (21) rating indicates the presence of flammable dust.

ATEX zone 0/20 certification

Zone “0” and Zone “20” indicates the virtually continuous presence of an explosive atmosphere. The zero (0) rating indicates the presence of flammable gas. The twenty (20) rating indicates the presence of flammable dust.

ATEX Certification Requirements

Equipment and devices must be tested and certified to be safe in an explosive atmosphere consistent with their likely use. A household air-conditioner, for example, needs only a CE certificate stating it meets the engineering requirements/standards for an a/c in the EU.

Something designated as safe in a dusty environment needs more significant proof and testing. There are many organisations that provide such training, but there are just as many already set up to provide certification for your existing and new products on a much faster timetable.

ATEX Certification Cost

The prices for ATEX Certification depend on the individual products and the complexity of the testing. Each item is going to be different. Generally speaking, the simpler the device the lower the cost, and conversely the more complexity, the more extensive the testing must be. This directly affects cost.

An example of extra costs engineering companies make when manufacturing certified equipment is testing cable connections using a force meter.

Indeed, zone two objects and devices will be less expensive than Class 0 devices or objects to certify. Mining and high-risk explosive atmosphere testing are more intensive than making sure a vacuum-cleaner bag doesn’t explode, fill the air with dust, and then ignite it. Something used a kilometre or two underground has to be failsafe – there are no second chances there.

ATEX Certifications Codes

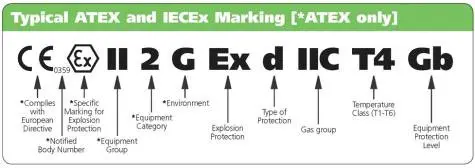

ATEX codes are alphanumeric strings consisting of a five-part prefix and a five part suffix. These codes represent harmonised standards so information equipment plates are consistent and readable anywhere in the E.U. Some manufacturers take an extra step and add a second suffix because they have certified the device for both GAS and DUST environments so as to indicate compatibility with multiple dangerous environments.

Prefix

The first code identifies it as CE compliant followed by a four-digit number identifying the Notified Body. Next you’ll see the EX hexagon, indicating that it has “explosive atmosphere” status. Following that is the Equipment Group number with “I” for mines and “II” for everything else.

Next you’ll see a code representing the Equipment group. M1 and M2 indicate mining equipment, and plain 1, 2, and 3 cover all the remaining possibilities outside of mining.

The last figure with be the environmental indicator—either G or D—to indicate whether it is for Gas or Dust.

Suffix

The suffix provides more detail about the protection level and how it is protected from explosion. It also elucidates what those hazards are.

It always starts with Ex to indicate protection against explosion. You’ll next see d, e, i(a,b,c), m(a,b,c), n(A,R,C), o, p(x,y,z,*), q, t(a,b,c), or pairs to show multiple qualifications, like eo, or de.

The “d” means flameproof; “e” refers to low risk of arcs, sparks, or hot surfaces; “i” is safe for Zone 0 or 20 because it uses very low energy, minimal low energy sparks, and no hot surfaces; “m” refers to isolating incendiary parts from the atmosphere (oxygen source); “n” refers to non-sparking and is confined to Zone 2 where explosive atmospheres are rare to non-existent; “o” refers to oil-immersion; “p” refers to pressurised environments; “q” refers to powder-filled environments; “t” refers to dust tight equipment.

Next is I, II, or III, for (respectively) mining-only, gas, or dust. II and III can be further appended with A, B, or C to provide additional information where A is more dangerous than C.

Next is line is the Temperature range for gases as T1-T6, indicating the highest temperature the equipment will reach, indicating how far from the combustion point of a given gas it will be, thus its relative safety.

For Dust, the letter T is followed by the maximum likely surface temperature in degrees Celsius. T100ºC, the boiling point of water, could be fairly common, and T230ºC would be just below the ignition-point of dry paper.

Finally, the last figure in the suffix is the Protection Level afforded by the equipment. Ma and Mb are strictly for mining applications, whereas you’ll see Da, Db, Dc, or Ga, Gb, Gc, for Dust and Gas, respectively.

ATEX Certification Mechanical Equipment

Mechanical equipment, also referred to as non-electrical equipment may also need to be ATEX Certified. A good example is the rotor blades of a drone. These blades generate static electricity when they are spinning. Moving mechanical parts such as spinning rotor blades could form a source of ignition.

Consider the implications of flying a drone over a petroleum cracking plant. In flight, the drone acquires a high static charge, which is relatively safe while it is airborne, but if it crashes or touches an object so that it discharges that static, that arc could set off a string of deleterious events.

ATEX Certification Courses

Courses for Certification abound, and we don’t look to promote any particular organisations. Select a good one (see their reviews from their students) that is relatively close by and which covers the topics you need or desire.

One of your primary tasks is to identify hazardous areas, and to learn the basic principles. You’ll need to understand the legal codes and requirements as well as the various types of equipment and test apparatus, and proper use thereof for assessments.

What you’ll be training for will vary but will probably include how to prepare ATEX EC Examination Certificates to provide the results of testing, how to make an Ignition Hazard Assessment (IHA), and how to apply the standards to reduce ignition sources. You’ll also need to prepare Declarations of Conformity (DoC). There is no escaping the paperwork!

ATEX Certification in Various Countries

Is ATEX certification applicable in North-America?

This simple answer is no, though we are seeing more ATEX-certified products, such as vacuum cleaners, being imported with that certification. North America relies on NFPA (National Fire Protection Association), OSHA (Occupation Safety Health Association), the CSA, and the NEC (National Electric Code) for its standards.

ATEX Certification US equivalent

The ATEX Ex rating does not carry official weight, and approvals must come from a Nationally Recognized Testing Laboratory (NRTL), which still includes reliable names like CSA, Intertek, TUV, and UL, among several others.

ATEX vs. IECEX

ATEX is acceptable anywhere in the EU for equipment to be used in potentially explosive atmospheres. IECEx, on the other hand, is internationally (globally) recognised. The important part to remember which differentiates them is that ATEX is driven by regulation and law, whereas IECEX is driven by harmonised standards. Your choice depends on where your sales will take place. If they are likely to be both within and outside of the E.U., it makes sense to get both certifications.

ATEX Certification UK

Brexit, for better or worse, is fait accompli. As a result, ATEX is a thing of the past in the U.K. Despite that, standards will remain the same, since there are no current plans to modify them. The name will change to UKCA, with this new symbol. Beneath the symbol itself will be the 4-digit code which identifies the certifying authority.

ATEX India

Electrical Consultants Association (ELCA) of India and the CSA are cooperating to provide ATEX certification for Indian Exporters selling products in the E.U. The certifying body will be the IECEx for the Indian Laboratory, and that will provide an associate office in Mumbai for CSA ATEX certifications in India for their exporters.

Indian manufacturers do not use ATEX, relying instead on IECEx certification, but the E.U. New Legislative Framework, specifies ATEX Directive 2014/34/EU (aka ATEX 114) and ATEX 153 for India’s products exported to the E.U. for use in potentially Explosive Atmospheres.

This will allow them to meet the EHSRs, or Essential Health and Safety Requirements, for equipment designed to work within specified potentially explosive atmospheres. It also addresses the design of protective equipment (explosion arrestors) for those same potentially explosive atmospheres.

Directive 2014/34/EU (aka ATEX 114) and ATEX 153 provide specifications for both electrical and non-electrical equipment (such as rotors and propellors on aircraft and drones) that can create static electrical charges and discharges, when devices are intended for use in potentially explosive dust or gaseous atmosphere.

Like other jurisdictions, it also specifies that manufacturers, their authorised representatives, importers, and their distributors, are responsible to ensure that their items meet EHSR requirements before being exported to the E.U.