Chances are that you have seen an ATEX rating, zone classification, or an EX rated logo on a piece of equipment before. But what does this indicate about the product?

This article explains everything you need to know about the definition of ATEX, approved products, certification, and more related subjects.

What Is ATEX?

The term “ATEX” is derived from the French words “Atmospheres Explosibles” and refers to European directives for controlling explosive atmospheres. These directives cover the minimum safety requirements for improving the health and safety of workers and the equipment and protective systems intended for use in these atmospheres.

In other words, these directives are designed to protect employees from explosion risks in explosive atmospheres. The ATEX directives are widely recognized and implemented, and industry professionals and companies across the European Union follow the guidelines.

Explosive atmospheres

Explosive atmospheres are defined as atmospheres containing a mixture of air and combustible substances under atmospheric conditions, in which the combustion can spread to the unburned mixture after ignition.

To clarify this definition a little bit: combustible substances include gases, vapors, mist, or dust. Subsequently, atmospheric conditions are defined as ambient temperatures and pressures. In other words, temperatures between -20 and 40 degrees celsius and pressures of 0.8 to 1.1 bar.

These atmospheres are present in many settings, such as:

- Oil and gas production facilities

- Chemical and pharmaceutical manufacturing plants

- Food and beverage manufacturing facilities

And other workplaces that contain, handle, or produce activities releasing flammable gases, vapors, or fine dust. In addition, leaks, spills, and over-pressurization can also create explosive atmospheres.

The Risks And How To Minimize Them

These atmospheres can pose a significant risk to workers because they have the potential to ignite and cause explosions. Therefore, following the guidelines concerning the corresponding atmosphere is crucial to minimize explosion risks and ensure safety.

Using Certified Equipment

A common way of minimizing risk is the removal of potential ignition sources because the goal is to prevent contact between these atmospheres and ignition sources. This is often done by using ATEX equipment.

Proper Zoning Classification Is Important

Employers are required to classify explosive atmospheres into different zones. In Europe, these zones are called ATEX zones. The size, location, and classification of these zones depend on the likelihood of occurrence and persistence of these atmospheres. Furthermore, the zones determine requirements such as the certification of the equipment used within that zone.

This brings us to the next question; What are ATEX zones?

ATEX Zones explained

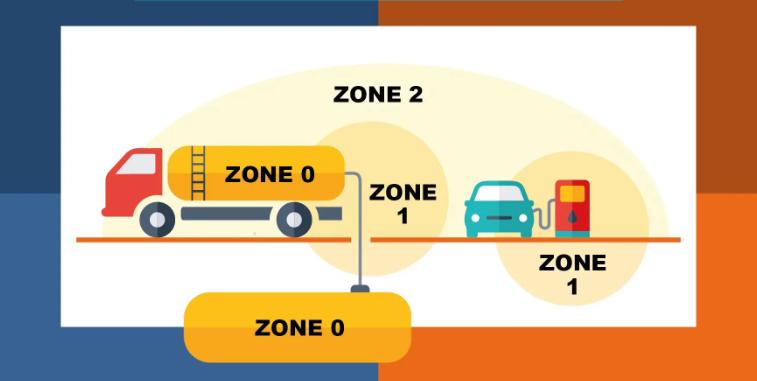

Now that we have learned more about the definition, let’s dive deeper into the different ATEX zones and their classification. The zones are divided into two types of hazardous areas based on the fuel that may be present in the air (gas or dust). Secondly, the hazardous areas are subdivided into different zones or categories.

All ATEX Zones & Equipment Categories

- Zone 0 / Category 1G

- Zone 1 / Category 2G

- Zone 2 / Category 3G

ATEX zones for dust

- Zone 20 / Category 1D

- Zone 21 / Category 2D

- Zone 22 / Category 3D

Zones 0 and 20

The classification of ATEX zones depends on the presence of explosive mixtures in the area. For example: “Zone 0 ATEX” means a continuous presence of explosive mixtures in the area. Equipment for zone 0 should still be working safely after two separate malfunctions. This also applies to Zone 20.

Zone 1 and 21

Next, zone 1 (and zone 21) means that explosive mixtures are likely to occur during regular operation. The equipment should still be working safely with one separate malfunction.

Zone 2 and 22

Lastly, zone 2 (and zone 22) classification means that explosive mixtures are not likely to occur during regular operation; if they will, they will be for a short time.

Compare ATEX and IECEx zones with NEC 500’s (North-America) Classes and Divisions in our PDF.

Logically, the zone classification determines how strict the standards are to be met, leading us to the question: what are ATEX standards?

ATEX Standards

For every different zone, there are different standards. These standards are compiled in the ATEX directive for controlling explosive atmospheres and may be used as an aid for developing products.

However, there is room for interpretation, and deviation from these standards is possible. Manufacturers do have to closely follow standards however. Usually a notified body tests equipment to verify that the standards are properly met by the manufacturer.

ATEX Directives

The directives cover the mandatory regulations concerning equipment and protective systems for use in explosive atmospheres. They also define conformity assessment procedures and safety and health requirements. National authorities are responsible for implementing and enforcing the directives. Companies that deal with explosive atmospheres must comply with the corresponding ATEX directives. The two different directives are:

- ATEX 114 (ATEX 2014/34/EU): describes the minimum safety requirements of equipment for manufacturers.

- ATEX 153 (ATEX 1992/92/EG): describes the minimum safety requirements for a safe working environment intended for employers.

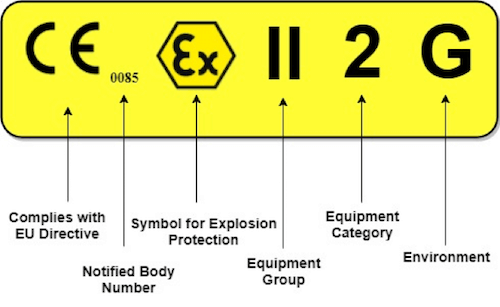

If you want to check whether a product conforms to specific standards or is Ex rated, you want to keep an eye on the “Ex” rating displayed on the right. Within the European Union, ATEX equipment must also be CE certified.

Product Marking

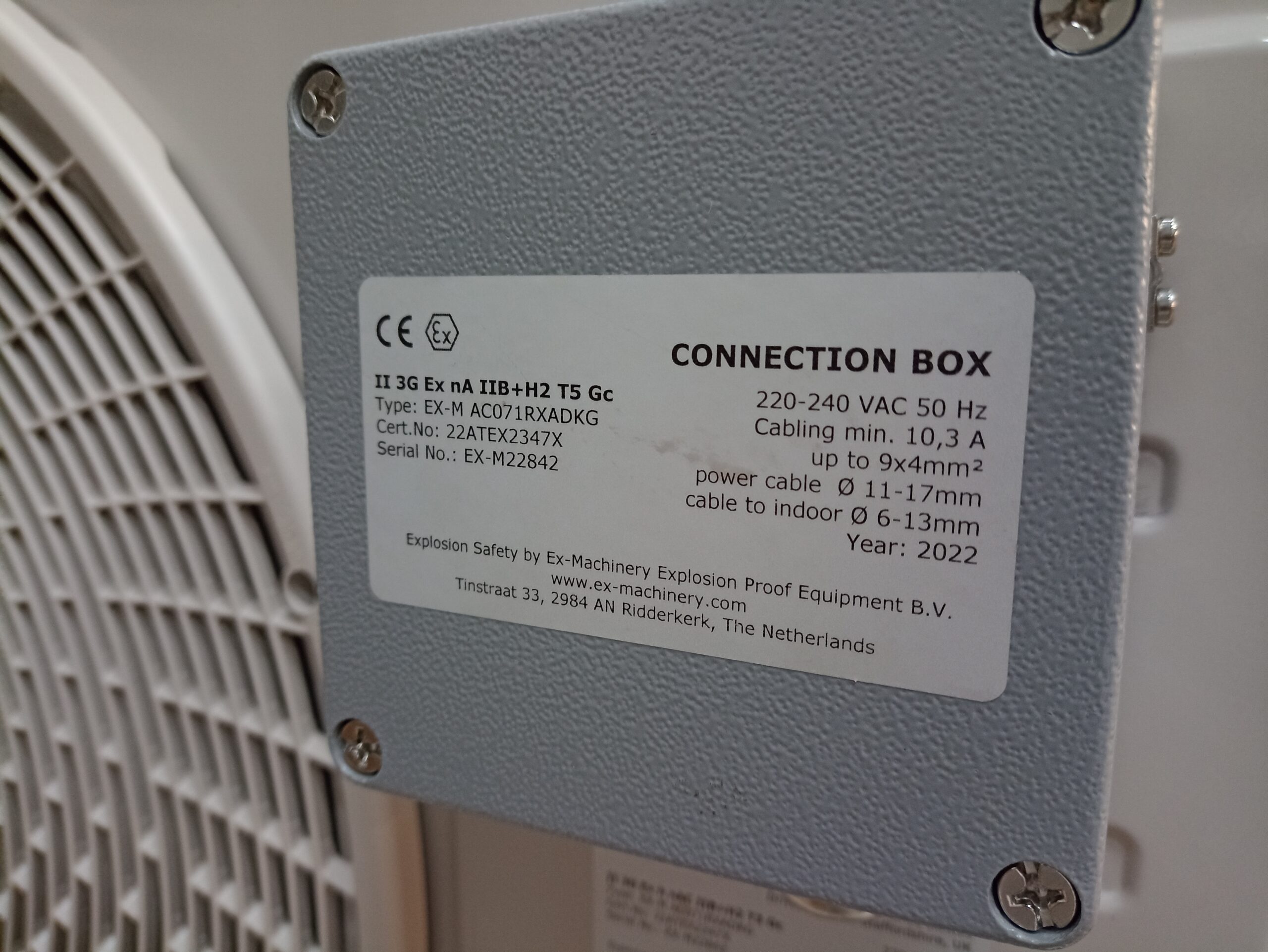

All certified products come with a marking, also called an ATEX rating label. For example, the label displayed below.

From this picture, we can conclude that the product is certified for use in Zone 1 (category 2G). The notified body has certified this product and is listed under “0085.” To clarify all the other markings and symbols on the label, we have made a table with the most common markings.

Product Marking Table – How To Read ATEX Product Markings?

| Definition | Marking | Explanation |

| Explosion proof | The product is ATEX certified. | |

| Equipment Group | I | For use in underground mines. |

| II | For use in all other places. | |

| Category | 1 (Zone 0/20) | An explosive atmosphere is continuously present. |

| 2 (Zone 1/21) | An explosive atmosphere is likely during normal operation. | |

|

|

3 (Zone 2/22) | An explosive atmosphere is unlikely during normal operation. |

| Environment | G (Zone 0/1/2) | Equipment is certified for use in environments with flammable gases. |

| D (Zone 20/21/22) | Equipment is certified for use in environments with dust. | |

| Temperature class | T1 | Maximum surface temperature of 450ºC |

| T2 | Maximum surface temperature of 300ºC | |

| T3 | Maximum surface temperature of 200ºC | |

| T4 | Maximum surface temperature of 135ºC | |

| T5 | Maximum surface temperature of 100ºC | |

| T6 | Maximum surface temperature of 80ºC |

Please be aware that this table does not cover every marking on ATEX products, for example, the protection methods. You should always consult an expert before (first-time) using, maintaining, or repairing any item in a potentially hazardous area.

ATEX Certification

Equipment must be certified before they are allowed to be used in corresponding zones.

Manufacturers’ Declaration Of Conformity

Roughly speaking, there are two types of certification. For zone 2 and 22, manufacturers are allowed to issue their own declaration of conformity. This is also often called ‘self certification’. This type of certification is frequently used for bespoke solutions with a lower volumes. Without this option, bespoke hazardous area solution would not be feasible.

Notified Bodies: Third Party Certification

And that brings us to third party certification. In this situation, a third party, called a notified body, will test and approve that the equipment is suitable for use in the designated zone.

Notified body certification can be costly because many tests need to be performed, for example, impact testing. And the notified body certification process is not free of charge, either. Oftentimes, multiple adjustments will need to be made before a product passes notified body certification.

Now you can see why self-certification is essential for realizing zone 2/22 bespoke solutions. Just imagine impact testing a one-of-a-kind multi-million dollar machine.

However beware, and we can’t stress this enough:

Notified body certification is mandatory for equipment used in Zones 0/20 & 1/21. Always check the notified body certificate before you buy or install.

Thank you for reading our article. If you have any questions or remarks, please contact our team via the contact form.

Lastly, we would like to share our cheat sheet – be sure to bookmark it!

Cheat Sheet [ATEX glossary]

- ATEX: A commonly used European directive to control explosive atmospheres.

- Explosive atmosphere: An area where there is a mixture of air and combustible substances under atmospheric conditions, in which the combustion can spread to the unburned mixture after ignition.

- ATEX Zone: An area marked as an explosive atmosphere ranked based on the danger of combustible gases, dust clouds, and mists. The classification of the zones depends on the presence of explosive mixtures in the area.

- Equipment Categories: A corresponding metric for the zones. Category 1G is the same as zone 0, and category 2G means zone 1, etc.

- ATEX Directives: the mandatory regulations covering equipment and protective systems for use in explosive atmospheres.

- ATEX Standards: harmonized standards composed by the directives for controlling explosive atmospheres that can aid in developing products.

- ATEX 114 / 2014/34/EU: A directive that describes the minimum safety requirements of equipment for manufacturers

- ATEX 153 / 1992/92/EG: A directive that describes the minimum safety requirements for employers.

- EX rating / ATEX rating: A rating that determines the suitability of a product for specific zones.

- Notified Body: A third party that tests products and certifies products.

- ATEX marking / rating label: the label which displays the rating, the equipment category, the notified body number, and other characteristics.

- ATEX Certification: Evidence that a notified body has tested the equipment and that the equipment is safe for use in explosive atmospheres.

- Explosion protection document: A mandatory document covering a specific area’s zones.

We hope that you have learned more about ATEX and related subjects. Please look at our other blogs, and don’t hesitate to contact us at info@cobic-ex.com.