Just recently, there was a massive dust explosion in the Turkish city of Derince that seriously injured 12 people. And here in the Netherlands, there was another dust explosion at a milk powder factory in Putten. The knowledge about explosion-proof dust extraction systems and all the necessary safeguards and explosion pressure relief measures is sorely lacking. There are only a handful of companies that really specialize in this area. JOA Air Solutions is one of them, for which I have worked the past 20 years.

Introducing John Meijer: An Expert in ATEX Training

With 20 years at JOA Air, I have honed my skills in designing, commissioning, and starting up explosion-proof dust extraction systems. Throughout my career, I observed that dust explosion hazards are often underestimated, both domestically and internationally. After 25 years immersed in the ATEX world, I felt compelled to share my knowledge with the next generation.

This journey led me to Quercus, where I once trained as an Ex designer and now teach nearly all IECEx modules. Over the past year, I have trained hundreds of students, realizing that comprehensive knowledge of dust explosion hazards is rare.

History of Dust Explosion Protection

So, where did it all begin? In the past, various companies in Belgium were already somewhat further ahead in providing knowledge and equipment for dust installations, such as pressure relief (bursting discs), explosion vents, and suppression systems. That’s why we used to collaborate a lot with companies like Isma and StuvEx in Belgium, where I also took training courses in dust explosion safety. Later, the company VDL also started offering more of this type of equipment in the Netherlands, and they are now an important player in this field as well.

Dust Extraction in Practice

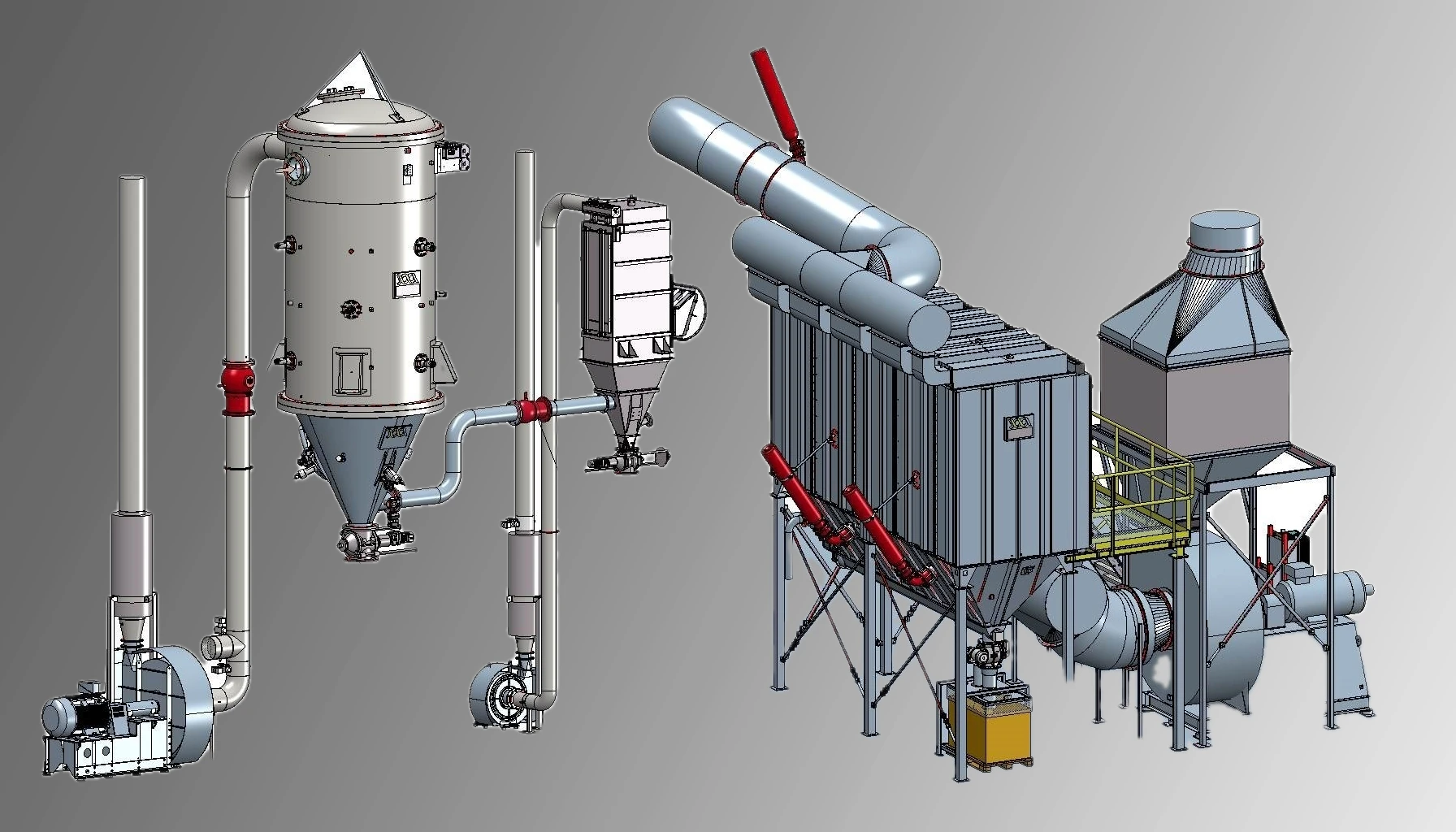

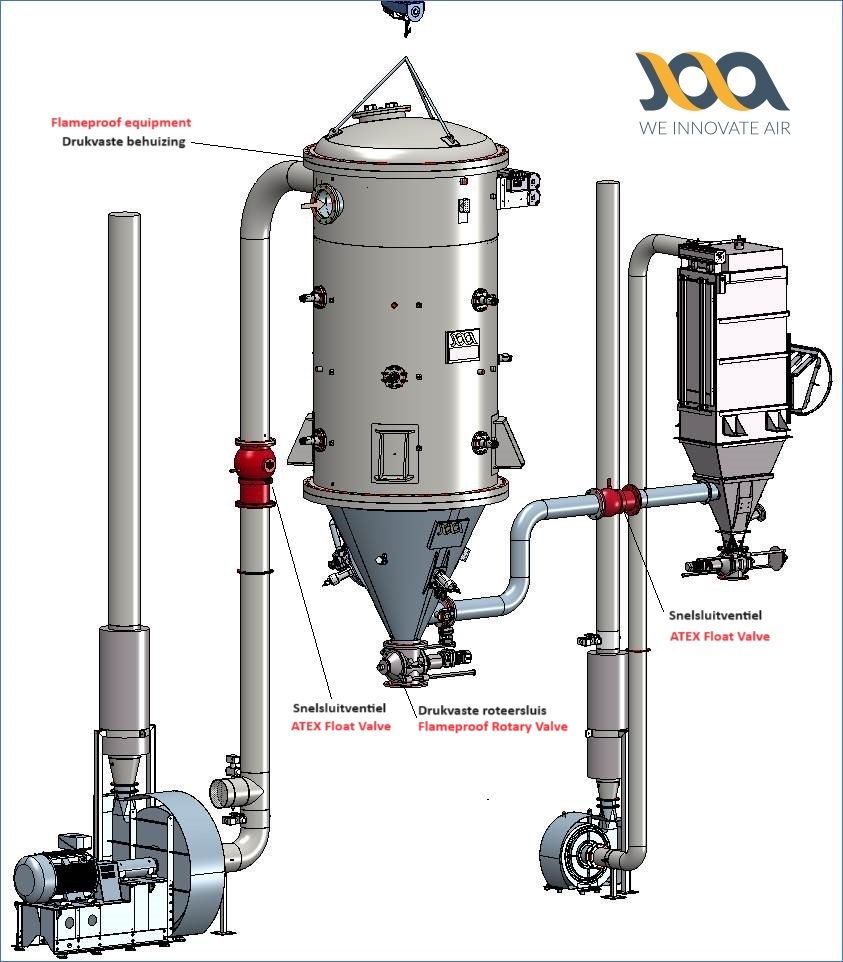

At JOA, we built large dust extraction filters in-house, with all the necessary provisions to comply with the explosion safety requirements. This requires meeting quite a few requirements. That’s why I always say, let everyone do what they’re good at, and don’t try to reinvent the wheel on your own. Instead, work with a party that, through decades of experience, knows all the rules and requirements and understands how to calculate and construct certain systems.

JOA has now built thousands of dust filter installations for all kinds of major multinationals worldwide in industries like plastics, chemicals, tobacco, pharmaceuticals, and food, and they know exactly what such an installation needs to comply with.

Risks of explosions in filter installations

JOA is the global market leader in innovative balanced air balancing systems – another crucial aspect of ATEX and explosion safety. How do you ensure, for instance, that you stay below the lower explosive limit in your exhaust ducts and minimize internal pipe contamination? They can offer good solutions for that.

So, how can dust explosion happen in filtration systems? For instance, clogging or the buildup of dust in pipes due to frequently low air velocities can create dust explosion hazards. Often, the lower explosive limit (LEL) values are not considered in pipes, unlike in filters where rupture discs are used. If it cannot be ensured that the concentrations within the pipelines stay below the LEL values, there are significant risks. Air flowing through these pipes can generate static electricity if the pipes are not properly grounded (not well bonded with other metal parts), which could serve as the ignition source for an explosion.

This risk is pertinent in various industries dealing with combustible dusts, such as plastics, pharmaceuticals, ink toners, and even flour in the food industry.

Case Study: Real Life Examples

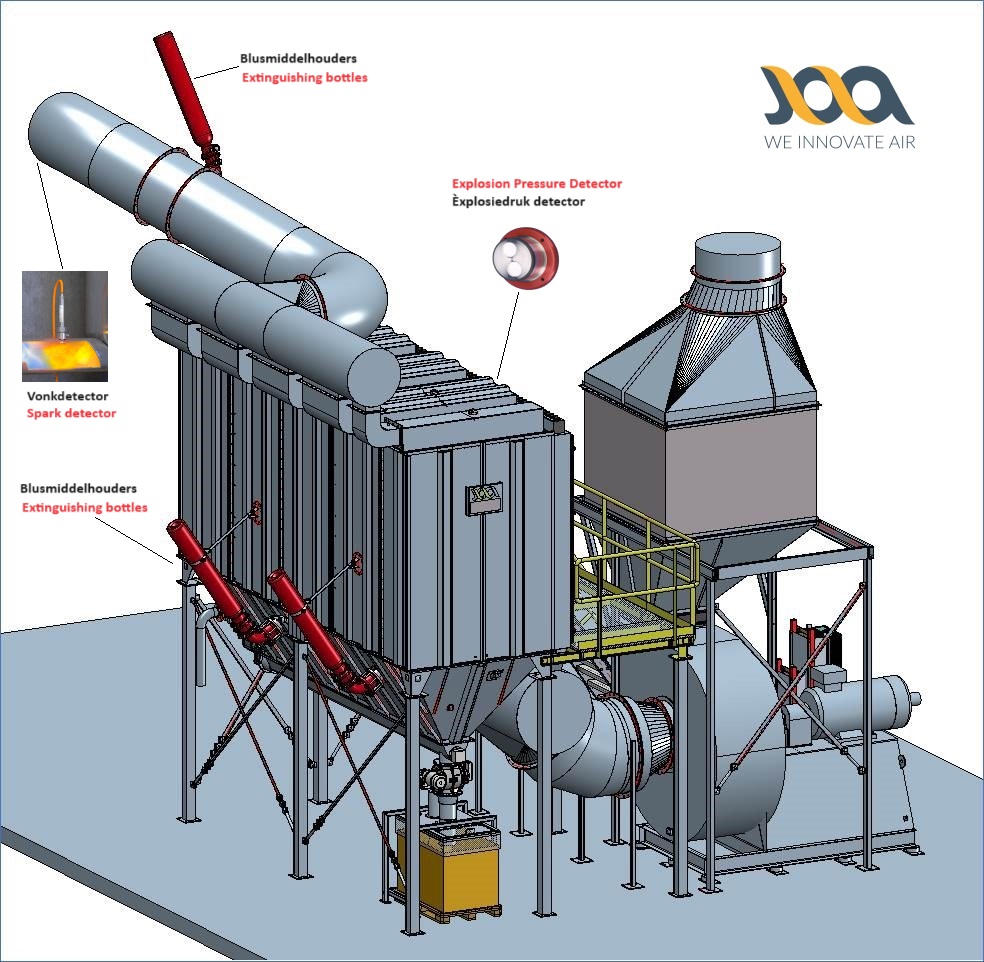

The filter is designed to be resistant to pressure shocks based on EN 14460, containing any explosion within it. This causes pressure to escape through gaps and crevices (flame paths). To prevent the explosion from spreading to other installations, explosion relief valves (Ventex valves) or explosion barriers are installed. These include a valve that can withstand a pressure surge, featuring a spherical ball inside.

In the event of an explosion, the ball is forced against a seal, and a pin locks the ball in place, effectively preventing the explosion from propagating to other equipment, such as a fan. For more detailed specifications, refer to the Ventex website.

In systems where there is no space for explosion venting panels or Ventex valves, suppression systems are employed. These systems utilize infrared and pressure sensors to detect the initial surge of an explosion. Within milliseconds of detecting this surge, the suppression system activates, effectively smothering the explosion before it can spread. The advantages of this approach include more compact construction, lower costs, and suitability for large installations where implementing protection is challenging.

Ex training at Quercus

At Quercus, we receive students from all directions for both theoretical and practical training in explosion safety. We have excellent training facilities with practical rooms in various locations in the Netherlands and abroad, where practical skills can also be trained and tested. If you have any questions, you can always contact us through www.QTS.nl.

Special thanks to Joa Air.