The Explosion Protection Document: Keeping Ex Zones Safe

In industries where explosion risks exist, safety is the top priority. One of the key tools for managing these risks is the Explosion Protection Document (EPD). Let’s dive into what an EPD is, why it matters, and what it should include.

What’s an Explosion Protection Document?

The Explosion Protection Document is a comprehensive report that shows how a company complies with safety regulations and manages ATEX (Atmosphères Explosibles) risks in the workplace. It’s not just about ticking boxes for legal requirements—it’s a crucial part of keeping people safe in potentially dangerous environments.

Why the EPD Matters

The EPD serves several important purposes:

- Ensures explosion risks are thoroughly assessed and managed.

- Protects workers in hazardous environments.

- Provides a clear picture of explosion risks within a facility.

Demonstrates a company’s commitment to safety and regulatory compliance

When Do You Need an EPD?

You need to create an EPD before starting work in any place where explosive atmospheres might occur. It’s not a one-time task; the document must be updated whenever there are significant changes to work areas, equipment, or procedures.

Before any classified zones are used for the first time, the explosion safety of the workplace must also be verified by competent professionals. This verification process should be documented and included in the EPD.

What’s Inside an EPD?

A solid Explosion Protection Document should include:

- Risk Identification and Assessment: A thorough analysis of where explosions could happen, including the likelihood of explosive atmospheres and ignition sources.

- Preventive Measures: Details on how you’re preventing explosions and reducing risks, covering both technical and organizational actions already taken and those planned for the future.

- Zone Classification: A breakdown of areas classified as explosion hazard zones based on the frequency and duration of the presence of explosive atmospheres.

- Equipment and Workplace Design: How work areas and equipment are designed, operated, and maintained with safety in mind.

- Employee Information: How workers are informed about risks and safety procedures.

- Coordination Plans: If multiple companies share a workspace, how they collaborate on safety in hazardous zones.

Understanding Zone Classification

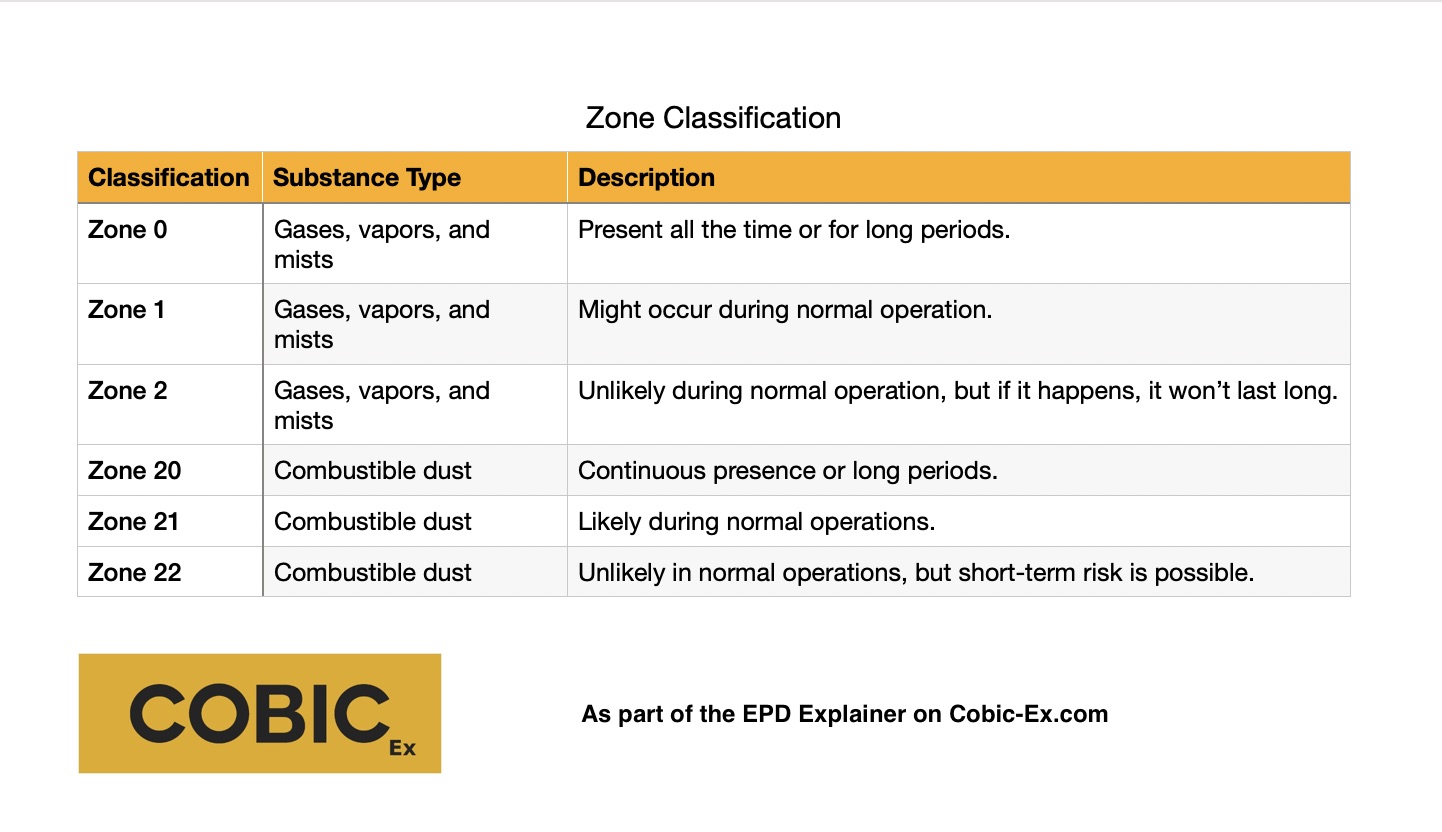

A key part of the EPD is classifying hazardous areas into zones. These zones indicate how likely explosive atmospheres might occur:

For gases, vapors, and mists:

- Zone 0: Present all the time or for long periods.

- Zone 1: Might occur during normal operation.

- Zone 2: Unlikely during normal operation, but if it happens, it won’t last long.

For combustible dust:

- Zone 20: Continuous presence or long periods.

- Zone 21: Likely during normal operations.

- Zone 22: Unlikely in normal operations, but short-term risk is possible.

The classification is influenced by factors such as the type of explosive mixture, ventilation levels, and release points.

Ventilation and Release Grades

When determining zones, the effect of ventilation must be considered as it plays a major role in the dispersion of flammable substances. Additionally, the frequency and duration of releases—known as the “Grade of Release“—help guide zone classification. Continuous releases correspond to more hazardous zones (Zone 0 or 20), while occasional or short-term releases lead to lower-risk zones (Zone 1 or 2, or Zone 21 or 22).

Machinery and Equipment Considerations

If machinery is located in hazardous areas, it must meet certain safety requirements, like the Essential Health and Safety Requirements (EHSR) on explosion risks. Equipment in these zones must also comply with ATEX Equipment Directive 2014/34 to ensure that it doesn’t pose an ignition risk. If machinery can’t fully prevent ignition sources, additional mitigation measures need to be in place.

It’s important that the equipment category on the Ex marking corresponds to the zone in which the equipment will be used. For instance, equipment marked as Category 2 in the ATEX system is designed for use in Zone 1 or Zone 21, meaning it provides a medium level of protection suitable for environments where explosive atmospheres are likely to occur occasionally. For example, a Dialight Ex Bulkhead light marked as Category 2 would be appropriate for installation in these zones, ensuring it meets the safety requirements for such hazardous locations.

This contrasts with Category 1 equipment, which offers the highest level of protection for Zone 0 or Zone 20, where explosive atmospheres are continuously present. Ensuring that the equipment category aligns with the designated zone is essential for maintaining safety and regulatory compliance.

Have a look at our full ATEX Lighting section to find which equipment matches your zoning requirements as indicated on the EPD.

Marking Hazardous Areas

Zone-classified areas should be clearly marked with EX signs at points of entry, where necessary. In cases where only part of an area is hazardous, floor markings (e.g., yellow and black stripes) can help distinguish these zones.

Creating an Effective EPD

Developing an EPD requires expertise in explosion protection and often follows industry standards, such as NEN-EN 1127-1 for risk analysis and NPR 7910 for zone classification. Regular reviews and updates keep the document relevant, ensuring ongoing safety for workers and compliance with legislation.

Wrapping Up

The Explosion Protection Document is more than just a legal requirement—it’s a vital tool for keeping workplaces safe where explosion risks exist. By thoroughly assessing risks, classifying hazardous areas, and detailing preventive measures, the EPD plays a key role in protecting workers and facilities from potentially devastating explosions.

Remember, safety is an ongoing process. Regularly reviewing and updating your EPD helps ensure it stays relevant and effective in safeguarding your workplace.