Most electrical equipment creates electric arcs. These are internal sparks that switches, connectors, motor brushes, and similar components can produce.

Furthermore, electrical equipment, like an iPhone used for an extended period, generates heat. This heat can turn the device into a potential ignition source (hot surface). Plant owners must prevent the presence of ignition sources in hazardous areas. They have multiple ways of achieving this. Intrinsic safety is one method to prevent electrical equipment from becoming an ignition source.

‘Intrinsically safe’ refers to several things within the industry, which can be confusing. In this article, we explain what intrinsic safety means from a technical point of view. First, we give the official definition, and then we compare it to another protection method: flameproof.

Additionally, we explore the terminology used in everyday life: what do people mean when they refer to an intrinsically safe product?

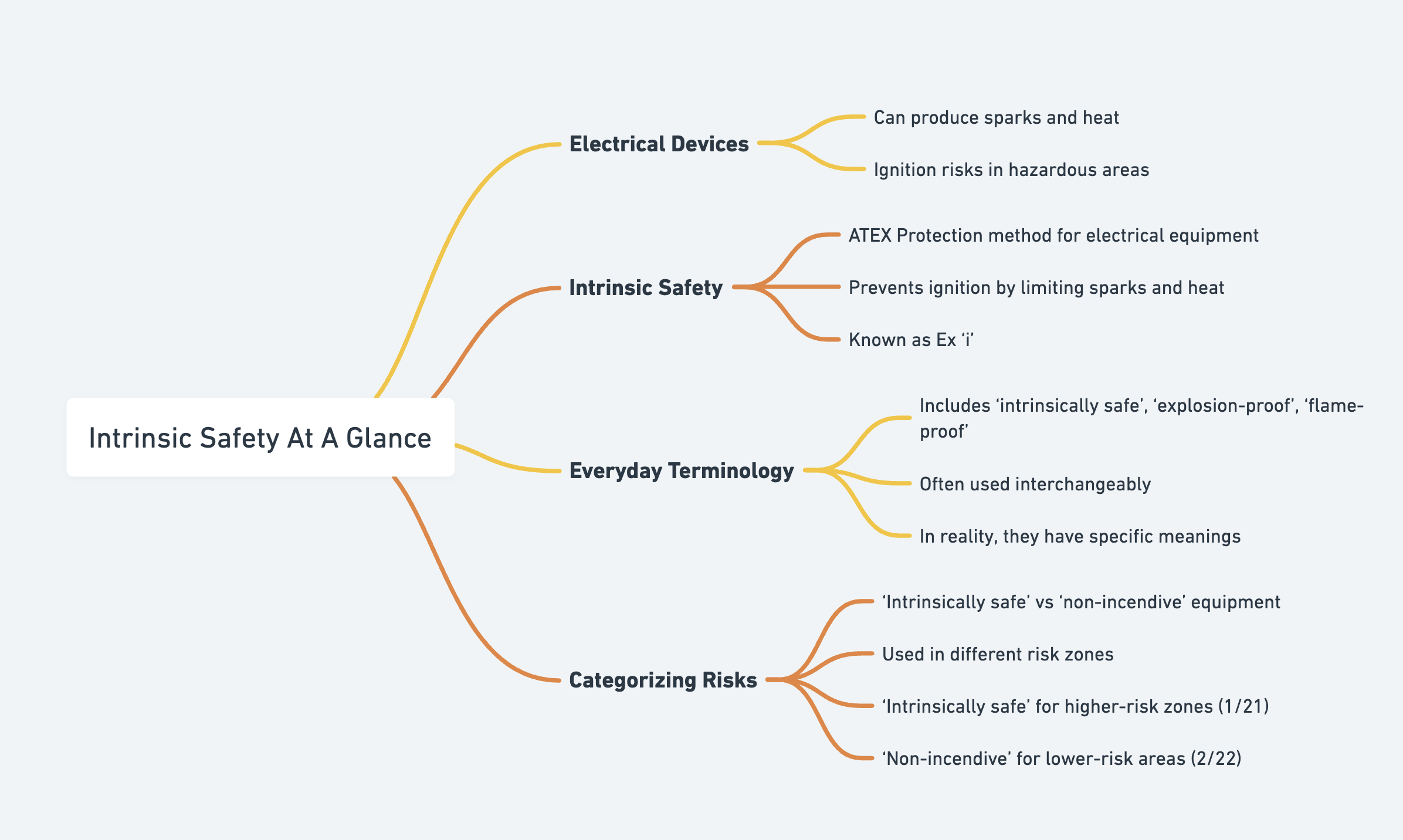

Intrinsic Safety At A Glance

In short, intrinsically safe has the following meanings:

- Electrical devices, including everyday items like iPhones, can produce sparks and heat, creating ignition risks in hazardous areas.

- Intrinsic safety is a design approach for electrical equipment to prevent ignition by limiting sparks and heat. This method is called Ex ‘i‘.

- In the industry, terms like ‘intrinsically safe’, ‘explosion-proof’, and ‘flame-proof’ are often used interchangeably, although they have specific meanings.

- The main difference between ‘intrinsically safe’ and ‘non-incendive’ equipment lies in their use: ‘intrinsically safe’ is for higher-risk zones (1/21), while ‘non-incendive’ is for lower-risk areas (2/22).

Intrinsically Safe Meaning

Hazardous area engineers design intrinsically safe devices to prevent the generation of sparks or heat sufficient to ignite an explosive atmosphere. Special protection techniques prevent electrical equipment from becoming an ignition source. Intrinsic safety, also known as Ex ‘i’, limits the thermal and electrical energy that can ignite a flammable gas or dust atmosphere.

When manufacturers design or modify equipment according to Ex ‘i’, several additional considerations come into play. These considerations may include, for instance:

-

Control of Component Temperature: Safety measures such as current limiting resistors and fuses are implemented to control the temperature of the components.

-

Reducing or Eliminating Internal Sparking: To reduce or eliminate internal sparking, designers limit the available energy throughout the system.

-

Managing Component and Track Spacing: Component and track spacing and isolation are crucial when there is a risk of dust or similar substances entering the circuit.

In conclusion, designers commonly employ intrinsic safety in equipment design for hazardous areas to prevent ignition sources. They do this by designing intrinsically safe circuits.

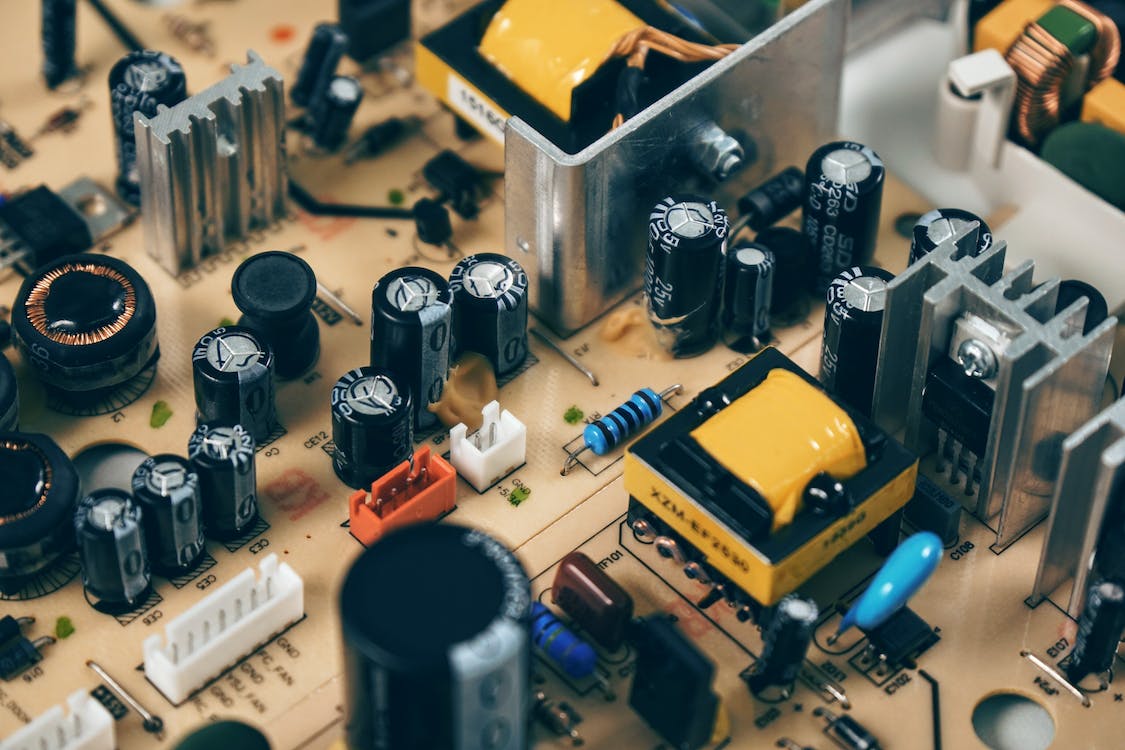

Most standard PCBs do not meet intrinsic safety standards. Click on the “plus” in the image for more information.

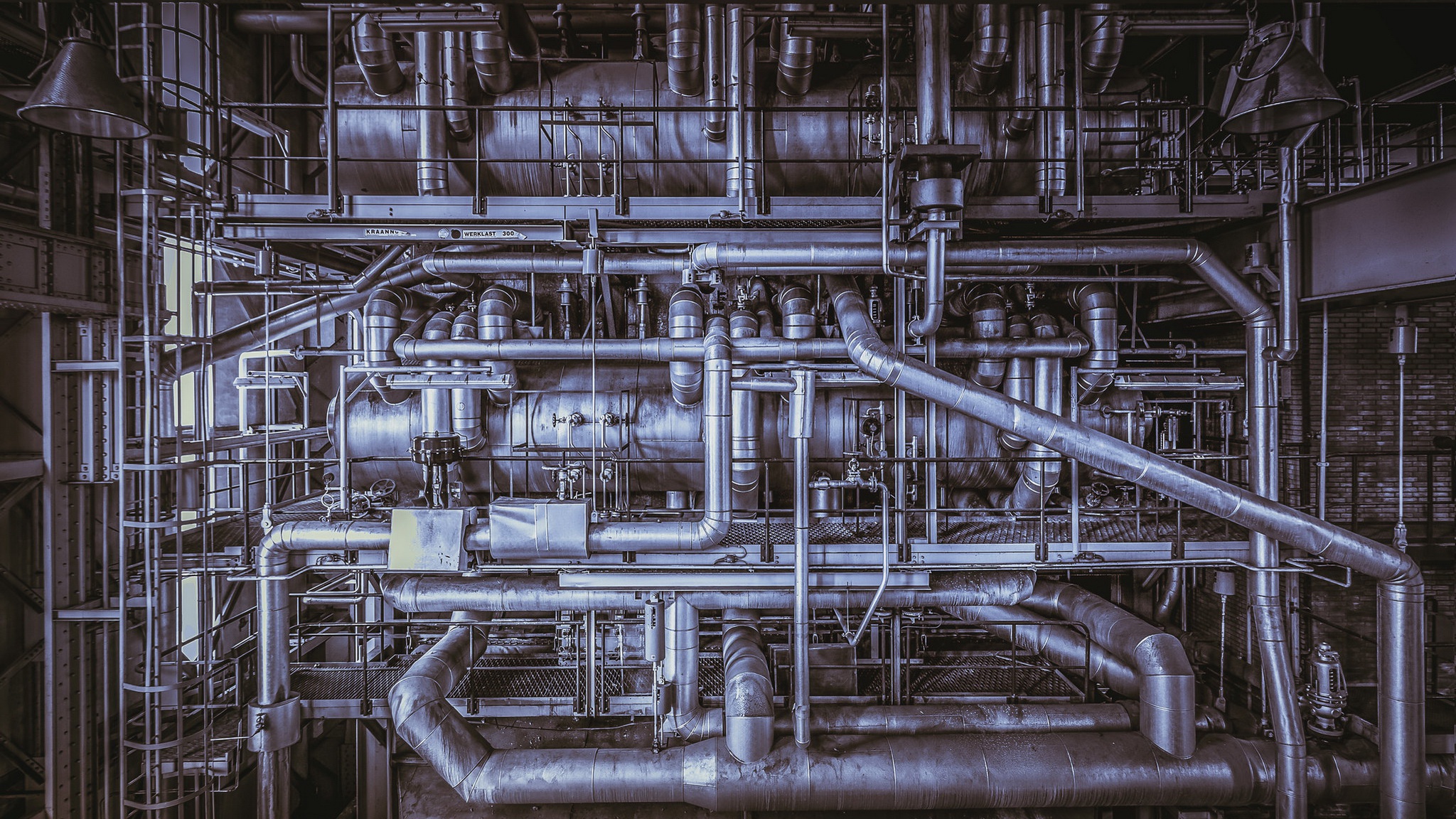

The Presence of Flammable Gases or Vapors

So, how does a standard PCB cause an explosion? Gases or vapors are often present in industrial environments. When these fuels (for example propane, hydrogen, or other flammable gases) escape and mix with air, they cause an explosive environment. Any electrical device could then set off an explosion. Therefore, these environments are prone to fire or explosion risks.

Igniting Hazardous Locations by Accident

This fuel (flammable gases or combustible dust) may come into contact with oxygen in the environment as a result of leakage. Any non-hazardous area electrical device operating in these environments could set off an explosion by accident.

Intrinsically Safe vs. Flameproof

Another common technique that hazardous area designers use to prevent explosions in hazardous areas is flameproof equipment. Flameproof equipment, often referred to as ‘explosion proof,’ differs slightly in its specific design and application. Flameproof equipment is designed with robust protection, allowing for the containment of any explosions within its structure.

This leads to the question of which risk reduction method is most effective. The answer depends on the specific situation, as both methods have their unique applications and are not mutually exclusive. Therefore, we have provided the advantages and disadvantages of each technique.

The Pros and Cons of Flameproof Equipment

- Advantage: The enclosure has a simple design, and this method is also suitable for high-power equipment.

- Disadvantage: The enclosure makes the equipment relatively heavy and expensive. Additionally, users must not open the enclosure while the equipment is powered on.

- Disadvantage: Complexity characterizes the maintenance of flameproof equipment. It is crucial that the enclosure is not damaged, as any damage can render the equipment unsafe for use in hazardous locations.

Flameproof equipment employs the Ex ‘d’ protection method and designers commonly use it for machinery intended for fixed installation.

The Pros and Cons of Intrinsically Safe Equipment

- Advantage: Intrinsic safety is relatively inexpensive to implement for the end-user, and it does not require special cabling. Maintenance tasks can often be performed live, allowing the power of the plant to remain on.

- Disadvantage: Intrinsic safety is only suitable for low-power equipment, such as smoke detectors and beacons, or mobile devices.

- Disadvantage: Oftentimes, the PCB must be redesigned, which drives up engineering costs. Therefore, to be economically viable, intrinsic safety design often requires high-volume production.

Intrinsically Safe Equipment

We have a wide variety of intrinsically safe equipment, such as smartphones, and cameras, available in our webshop. Additionally, Cobic-Ex offers a range of intrinsically safe torches.

However, it’s important to note that using an intrinsically safe device alone may not be sufficient to mitigate all risks in an industrial location. Users need to operate and maintain the equipment in accordance with the user manual. For example, users may not charge an intrinsically safe phone within an explosive atmosphere.

Intrinsic Safety Barrier

What exactly does the intrinsic safety barrier, a crucial concept in hazardous area design, entail? It limits the energy that can be transferred from a safe area to a hazardous area.

Positioned between the control equipment and the devices in the hazardous area, the barrier reduces the energy input into hazardous areas, thereby preventing the ignition of potentially explosive atmospheres.

There are two types of intrinsic safety barriers:

- Isolated Barriers: These provide galvanic isolation to prevent signal distortion and dangerous surges in measurement and control circuits. Additionally, they convert, standardize, and split measurement and control signals.

- Zener Barriers: Also known as ‘shunt-diode safety barriers,’ these barriers prevent the transmission of high energy levels from neutral to hazardous areas.

The figure below demonstrates how the barrier functions.

Intrinsic Safety and ATEX

It’s crucial to understand the connection between intrinsic safety and the ATEX directive, especially in the context of ATEX zones.

How do ATEX and intrinsic safety interrelate? Both ATEX and intrinsically safe equipment are designed for use in hazardous areas, but they differ in their approach.

The ATEX directive sets specific minimum safety requirements for managing explosive atmospheres. Among the various ATEX protection methods available, one key method is intrinsic safety.

In summary, the use of intrinsically safe equipment is a vital strategy for mitigating risks in compliance with ATEX standards. Intrinsic safety is a protection method used in the design of hazardous area equipment in compliance with the ATEX Directive.

Levels of intrinsic safety (ia, ib & ic)

Protection method ex i has 3 safety levels under ATEX regulations. Namely: ia, ib and ic. These safety levels relate to equipment categories and zones in the following manner:

ic – zone 2/22 – equipment category 3 – medium danger level

ib – zone 1/21 – equipment category 2 – high danger level

ia – zone 0/20 – equipment category 1 – highest danger level

Terminology: Intrinsically Safe vs. Explosion Proof

Within the industries that deal with hazardous areas, there are many synonyms for what are essentially Ex certified products. Ex certified means that the product is suitable for use in a potentially explosive atmosphere. There are many different types of product certifications based on region, for example, ATEX certification (EU), IECEx (World Wide), or UKCA/UKEX (United Kingdom)

Differences in Terminology, Synonyms?

In the United Kingdom, people commonly use the term ‘intrinsically safe’ to refer to Ex certified products. This can be unclear because it does not necessarily mean that the product uses intrinsic safety as a protection method.

In the United States and other countries, people often refer to Ex-certified products as ‘explosion proof.’ This terminology may also be confusing because it suggests that the product could withstand an explosion, which is not the case. The product is designed to not form an ignition source.

Keep this in mind: when people refer to a product as ‘Intrinsically Safe’, ‘Explosion Proof’, ‘Flameproof’, or ‘Ex Certified’, they usually mean a product that is suitable for use in explosive atmospheres.

Intrinsically Safe vs. Non-Incendive: Categorizing

By now, you’ve learned that ‘intrinsically safe’ can mean a protection method or simply denote suitability for use in hazardous areas. Additionally, ‘Intrinsically Safe’ is a term used to categorize equipment for hazardous areas, adding another layer to its meaning.

As you know, hazardous areas are classified into zones, based on their nature and the expected danger. Intrinsically safe products are typically used in Zone 1 (gas) and 21 (dust), which are considered more dangerous than Zone 2 (gas) and 22 (dust), where non-incendive products are certified.

In conclusion, when a product is referred to as intrinsically safe, explosion proof, or flameproof, it’s important to ensure that the certification matches your specific location and hazardous area requirements. If you have any doubts or need further clarification, feel free to contact us.

The Takeaway

We hope this article has provided you with a clear understanding of the meaning of intrinsically safe, intrinsically safe equipment, and related concepts. At the end of the day, every company is dedicated to protecting people from hazardous locations from an explosion risk, caused by combustible dust or flammable liquids in the industrial environment.

In short, ‘Intrinsically Safe’ refers to a protection method (Ex ‘i’). In the industry, it is often used as a synonym for ‘explosion-proof’ and ‘flame-proof’. Importantly, it specifically categorizes equipment as suitable for the more hazardous zones 1/21, rather than for the less hazardous zones 2/22

Please visit our blog page for more information on these subjects. Should you have any inquiries or comments, do not hesitate to contact us at info@cobic-ex.com.