Ingress Protection EN/IEC (World Wide)

EN/IEC 60529 is a European and IEC standard that outlines the official method for classifying the effectiveness of electrical equipment enclosures in preventing the entry of foreign objects, like dust and moisture.

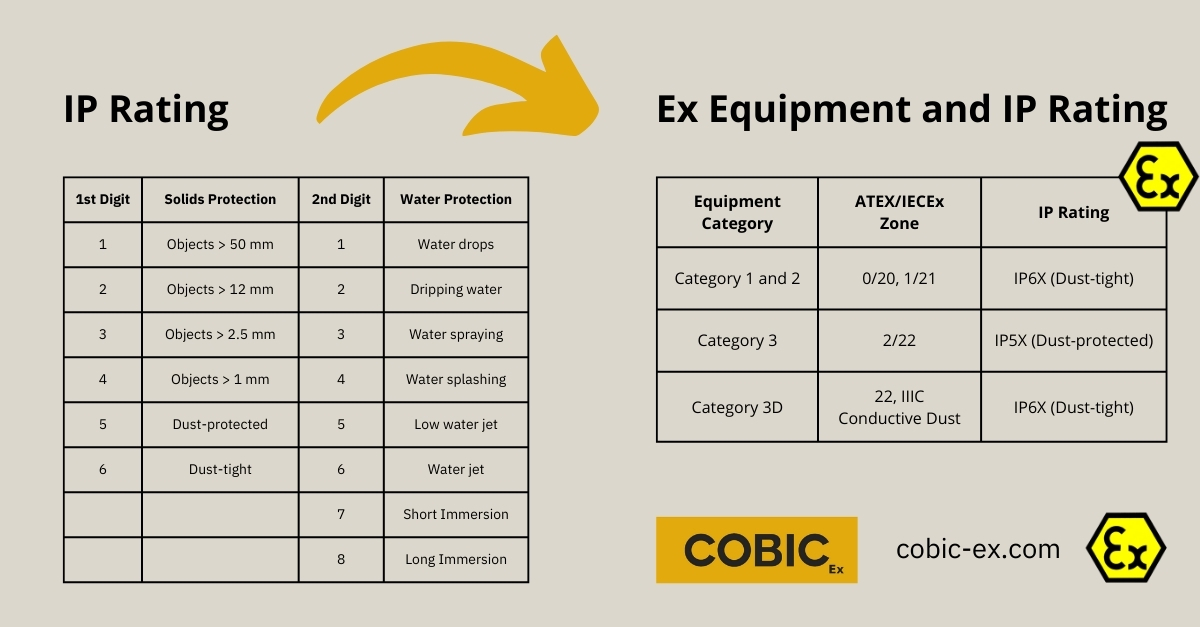

This system is known by the initials IP (Ingress Protection), followed by two numbers. If a device is only rated for one type of protection, an “X” replaces the digit for the other type.

The first number (ranging from 0 to 6) signifies how well the enclosure prevents the entry of foreign objects and dust. The second number (ranging from 0 to 8) shows the level of protection against water intrusion.

| First Digit | Solids protection | Second Digit | Water Protection | IP Rating |

|---|---|---|---|---|

| 0 | None | 0 | None | None |

| 1 | Objects > 50 mm | 1 | Drops of water | IP11 |

| 2 | Objects > 12 mm | 2 | Dripping water | IP22 |

| 3 | Objects > 2.5 mm | 3 | Water spraying | IP33 |

| 4 | Objects > 1 mm | 4 | Water splashing | IP44 |

| 5 | Dust-protected | 5 | Low-pressure water jets | IP55 |

| 6 | Dust-tight | 6 | Water jets | IP66 |

| 7 | Short Immersion | IP67 | ||

| 8 | Long Immersion | IP68 |

North-American IP Ratings

In the United States, the classification of enclosures for electrical equipment is governed by the National Electrical Manufacturers Association (NEMA) Standard Publication No. 250.

Unlike the IEC system, which primarily focuses on protection against dust and water intrusion, the NEMA standards consider a broader range of environmental factors, including coolants, cutting fluids, corrosion, icing, and hail. Due to these additional considerations, the degrees of protection defined by NEMA cannot be directly compared to those of the IEC.

Consequently, any attempt to align NEMA and IEC classifications should be seen as a general guide rather than a precise equivalence.

| NEMA (USA Rating) | IP Rating EN/IEC (Worldwide) |

|---|---|

| 1 | IP10 |

| 2 | IP11 |

| 3 | IP54 |

| 3R | IP14 |

| 3S | IP54 |

| 4 and 4X | IP56 |

| 5 | IP52 |

| 6 and 6P | IP67 |

| 12 and 12 K | IP52 |

| 13 | IP54 |

IP Ratings Under ATEX and IECEx

Under ATEX and IECEx, electrical equipment that is “protected by an enclosure” is designed to keep dust out to prevent any risk of ignition. In hazardous areas, the presence of an explosive atmosphere means that any source of ignition could lead to an explosion, underscoring the importance of preventing ignition.

Flameproof enclosures (Ex ‘d’) and restricted breathing enclosures (Ex ‘nR’) are a great example. If substances like aluminum dust or powdered sugar enter these enclosures, they could ignite, leading to hazardous situations..

| Equipment Category (Group II) Electrical Equipment |

ATEX/IECEx Zone | IP Rating |

|---|---|---|

| Category 1 and 2 | 0/20, 1/21 | IP6X (Dust-tight) |

| Category 3 | 2/22 | IP5X (Dust-protected) |

| Category 3D | Zone 22 Conductive Dust Environment |

IP6X (Dust-tight) |

Zones 0/20 and 1/21

For certain categories of equipment, specifically Group II, categories 1 and 2, the enclosures need to meet IP6X specifications, meaning they are dust-tight and completely prevent dust from entering.

Zones 2/22

On the other hand, equipment in Group II, category 3 typically needs to meet IP5X specifications, which offer dust protection but to a slightly lesser degree.

Conductive Dust Exception for Zone 22

However, there’s an exception when it comes to environments with conductive dust. In these scenarios, even the equipment intended for use in Zone 22 (which falls under Group II, Category 3D) must adhere to the more stringent IP6X dust-tight standards. This ensures maximum protection. Alternatively, when it’s cost-effective, you might opt for equipment from Group II, categories 1 or 2, which already meet these higher standards.

Example of IP rating on Explosion Safe Equipment

The Ex (explosion proof) marking on equipment indicates its suitability for use in hazardous environments. Let’s decode the below Ex marking on the Getac ATEX Tablet as an example.

- Ex II 3G Ex ic op is IIC T4 Gc

- Ex II 3D Ex ic op is IIIB T130°C Dc

These markings reveal the tablet’s certification and capabilities:

- Ex signifies that the device is designed to be explosion proof.

- II indicates it’s for use in places marked as Group II.

- 3G and 3D specify the device’s suitability for Zone 2 (gases) and Zone 22 (dust) environments, where hazardous atmospheres are present but not expected to occur in normal operation.

- Ex ic means it has an intrinsic safety level ‘ic’, suitable for use in Zone 2.

- op is refers to optical radiation with intrinsic safety, indicating it’s safe from ignition risks due to optical sources.

- IIC and IIIB denote the type of hazardous material the device can be safely exposed to— IIC for gas atmospheres with the highest explosive risk and IIIB for non-conductive dust.

- T4 and T130°C show the maximum surface temperature of the device, ensuring it won’t ignite specific gases or dust.

- Gc and Dc indicate the level of protection provided against gas and dust, respectively.

Given the device’s IP65 rating, found in the datasheet, it exceeds the minimum requirement of IP5X for use in Zone 22, highlighting its effectiveness against dust ingress, including conductive dust.

However, despite the device meeting the IP-Rating requirements, its rating for IIIB instead of IIIC means it cannot be used in environments with conductive dust.

If you’re unsure which Ex equipment suits your particular situation, do not hesitate to reach out to us at info@cobic-ex.com