Have you ever wondered about the likelihood of a dust explosion occurring? Consider this: the US contributes 24% to the world’s GDP, and if we scale that with the occurrence of dust explosions (about 30 per year), it suggests a staggering 125 dust explosions globally per year – that’s one every 2.9 days!

In this article, we break down what dust explosions are, why they happen, and how to prevent them. Before we dive in, here are the key takeaways to quickly address your burning questions.

Dust Explosions – Your Questions Answered

What Are (Dust) Explosions?

- Combustible dust is one of the three elements needed for a dust explosion, serving as the fuel. Oxygen and an ignition source are also required.

- Types of explosions include deflagrations (sub-sonic to sonic) and detonations (transonic or ultrasonic).

Fuel Sources: Which Dusts Are Combustible?

- Numerous materials can act as fuel for dust explosions, ranging from sawdust and paper to rubber, powdered metals, coal dust, and even human skin cells (household dust).

What Is Confinement?

- Confinement in dust explosions refers to the containment of dust particles in a limited space where accumulated dust can rapidly combust if ignited, increasing the explosion’s force.

Primary vs. Secondary Dust Explosions:

- Most dust explosions are secondary, initiated by a triggering event and sustained by the launching of accumulated dust, creating a self-sustaining and potentially devastating chain reaction. This dust cloud is capable of causing a devastating explosion.

Prevention Strategies:

- Industrial processes, such as recycling, pharmaceutical manufacturing, and coal mining, are prone to dust explosions.

- Dust explosion prevention revolves around the Three C’s: Contain, Capture, and Clean. Effective housekeeping, proper cleanliness practices, and dust collection systems play key roles in reducing risks.

Types of Explosions

First, it is important to understand that there are two types of explosions. The naturally occurring ones are sub-sonic to sonic, typically called deflagrations, meaning they are at or below the speed of sound. The transonic or ultrasonic explosions, those that travel faster than the speed of sound, are called detonations and generally require human interference and/or technology.

Detonations: Man-made

Detonations are used for demolition, mining, and often for warfare. The term is often misused to mean “an explosion of any type”. High explosives, being a manufactured product, have extremely predictable explosivity characteristics, and generate shockwaves that do the bulk of the work with little flame. Low explosives (fireworks, black powder, and nitrocellulose) only deflagrate.

Deflagrations: Dust Explosions

Deflagrations occur when sufficient flammable dust particles are suspended in air densely enough that an ignition source, whether a spark, open flame, or hot surface can cause even a single one to ignite. Being incredibly tiny, such particles have a massive surface area compared to their volume. The particle consumes its entire fuel supply in a moment, expanding instantly to many times its size.

This expansion triggers several more surrounding particles to ignite, causing a cascade effect. Each particle ignites many more, blossoming into a flaming wavefront expanding uniformly in all directions, through the dust cloud.

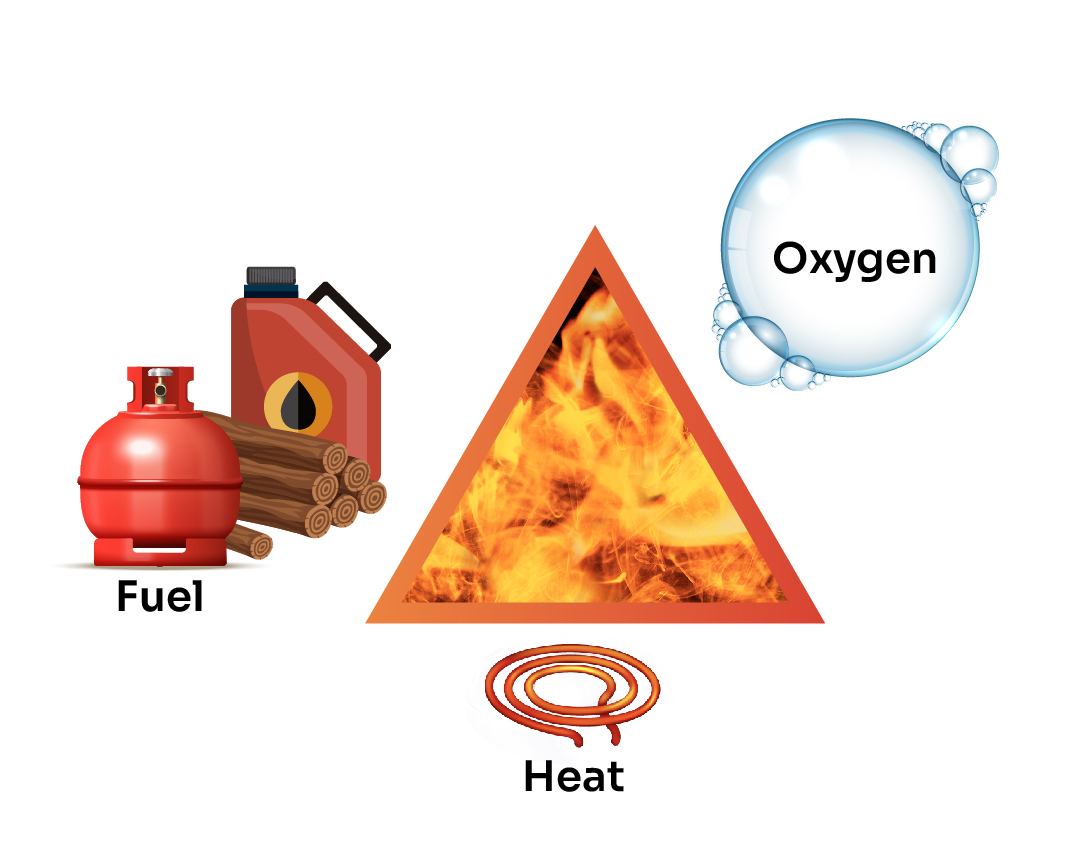

The Fire Triangle

Dust explosions occur when all three elements of the fire triangle – fuel, oxygen, and heat (ignition) – are present. In this context, various substances that satisfy the fuel component can potentially trigger a dust explosion. Further in the article, a comprehensive list of combustible dust categories and examples is provided.

Ignition sources

The following are common ignition sources:

- Friction sparks

- Electrical sparks

- Open flames (e.g., torches, candles)

- Overheated machinery

- Static electricity discharge

- Faulty electrical equipment

- Smoking materials (e.g., cigarettes)

- Exothermic chemical reactions

- Lightning strikes

- Welding and cutting tools

To prevent ignition in hazardous areas, companies make use of Ex certified equipment. In short, this equipment in such a way that it can not form a source of ignition under any circumstance.

If you’re not yet acquainted with the fire triangle, we recommend checking out our article for a comprehensive overview.

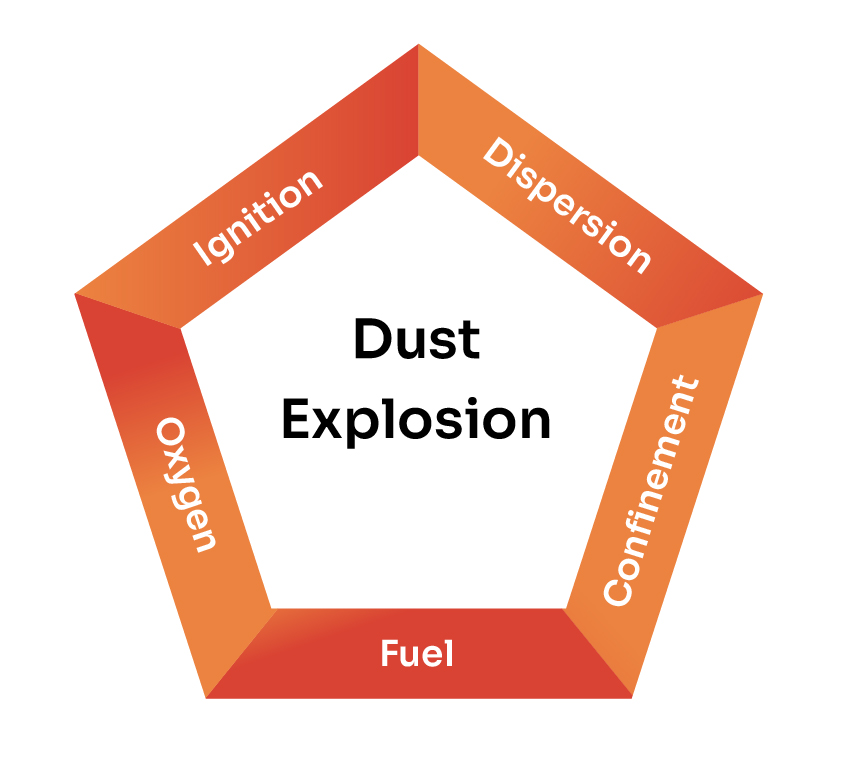

The Dust Explosion Pentagon

Building on the earlier discussion of the fire triangle, it’s important to understand that dust explosions require five key components, as outlined in the Dust Explosion Pentagon. This concept extends beyond the Fire Triangle’s requirements of Ignition, Fuel, and Oxygen, by adding two more critical factors.

Dispersion

These include the correct density of dust particles suspended in the air (dispersion), where their proximity enables a cascading effect, and confinement, which is essential for the explosion to occur.

Confinement and Explosive Pressure

It is nearly impossible to trigger a dust explosion outdoors because material can disperse too rapidly. It’s not impossible, of course. In some worldwide festivals, particularly throughout Asia, people colour corn starch to toss in the air, or at each other, to create huge clouds of pink, yellow, purple, red, green, and blue. Doing that in the “bowl” of a roller blade skate-park might be sufficiently confining to cause an explosion.

A 2015 incident in Taipei was not a dust explosion, but rather an airborne fire that burned 508 people, and killed 15. About 200 were in critical condition after the 40-second air blaze. If it had been confined, the death toll could have been much worse.

Confinement occurs when dust particles become enclosed in a restricted area, such as a room or inside machinery. This trapped dust will build up explosive pressure when it ignites. Confinement transforms a mere burning of dust into a potentially catastrophic event.

What Dusts Can Be A Fuel Source?

Sawdust can make a good fuel, particularly if it is very dry from insect infestation of lumber, as learned by two saw mills in British Columbia, in Canada. Dead trees, killed by pine beetles, were responsible for both of these explosions.

Similarly, paper dust, rubber dust, powdered milk or sugar, flour, spices, cocoa, coffee, tobacco, powdered light metals, coal dust, and organic fabric dusts in a clothing factory can be perfect. Other fuels include soaps, many plastic dusts, process additives found in pharmaceutical labs, and even biosolids from water treatment, blood dust in a slaughterhouse, or human skin cells (household dust) accumulating in your attic! or human skin cells (house dust) accumulating in your attic! Fortunately, there is no confinement in the attic. And hopefully, there is not enough dust to cause a fire…

Full list of common combustible dusts:

| Dust Category | Examples |

|---|---|

| Foods | Flours, starches, sugars, powdered milk, corn meal, cocoa powder, whey, cereal, spices, and gluten. |

| Agriculture and Grains | Wheat, corn, barley, oats, and soybeans. |

| Metals | Aluminum, iron, magnesium, nickel, niobium, tantalum, titanium, zinc, and zirconium dusts. |

| Wood | Sawdust and cellulosic dusts, including dusts from paper, cardboard, paper towels, facial tissue, and other paper products. |

| Plastics | Resins (e.g., melamine, epoxy, phenolic), polymers (e.g., polyethylene, polyvinylchloride, polyacrylamide, polyacrylonitrile), and copolymers. |

| Chemicals | Adipic acid, anthraquinone, dextrin, lactose, paraformaldehyde, sodium stearate, and sulfur. |

| Coal and other Carbonaceous Materials | Bituminous, subbituminous, lignite, charcoal, petroleum coke, and carbon black. |

| Other | Textiles, biosolids, soap, and pet food. |

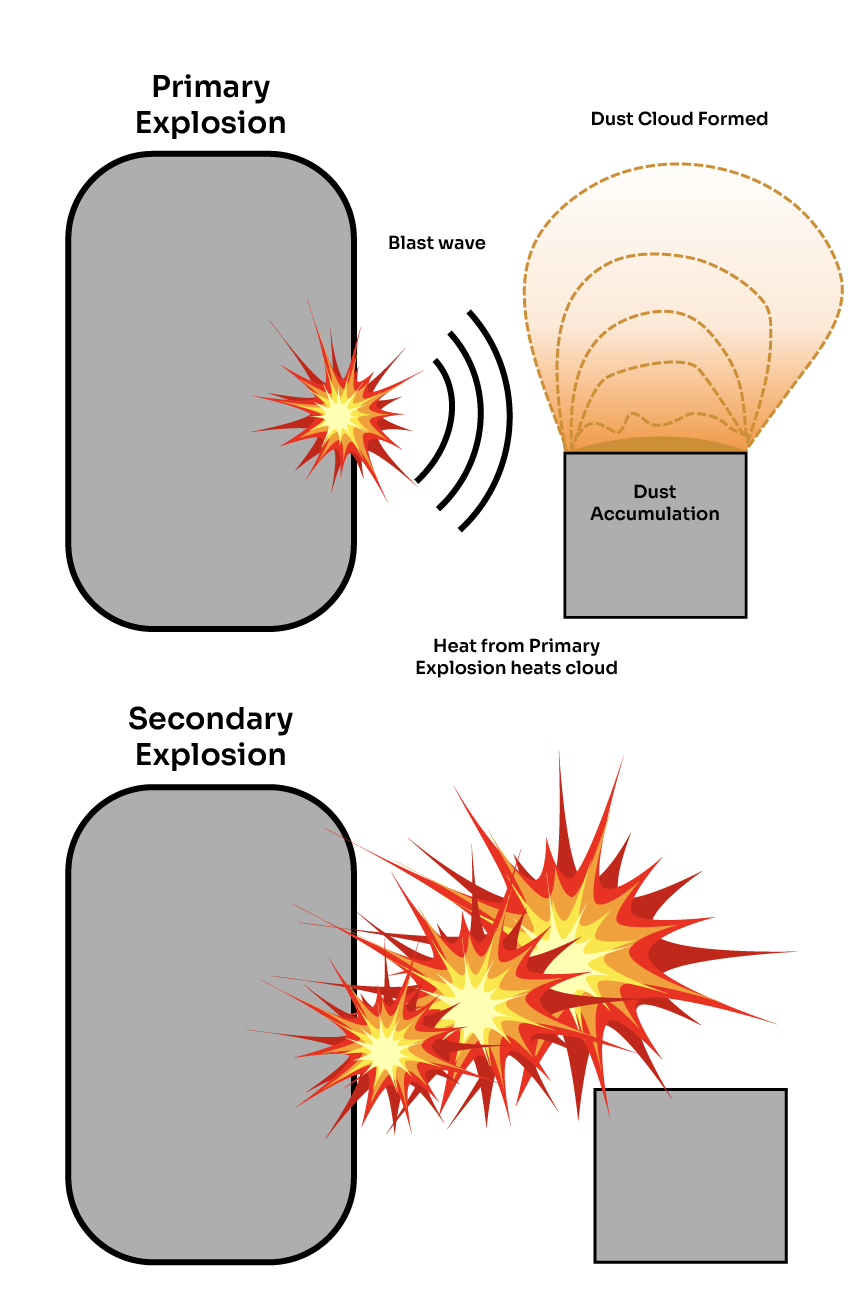

Primary vs. Secondary Dust Explosions

Most dust explosions are secondary. The triggering event might be a boiler bursting, or even some relatively trivial bang or pop, but the follow-on effect is that it can cause the launching of accumulated combustible dust which is then set ablaze by the remnants of the original small explosive event. This is what we refer to as the primary explosion.

Once that happens, not only does the initial flame sustain the action, but the pressure wave surrounding the flame front tosses up even more material, literally adding fuel to the fire. It is now entirely self-sustaining and will run until the fuel is all spent. Once this dust cloud catches fire, it will set off a secondary dust explosion. Secondary dust explosions can be extremely devastating, as you will learn from the examples listed later in this article.

Industrial Processes Prone to Dust Explosions

Recyclers, especially for metals, are prone to dust explosions. Mixed recycling gives even more opportunities to create dusts that increase their explosivity in combination.

Making pharmaceuticals requires “inert” fillers (like corn starch) to make tablets. A tablet may weigh 1000 mg (one gram) to deliver 10 or 15 mg of medicine. Seemingly, it’s for sales to make the pill look bigger and more impressive to raise the price. Conversely, if too small to print on, identifying products would be difficult.

Other problematic industrial processes include coal mining, paper manufacturing, book printing, operating grain silos, sugar or grain refining, and much more. What it all comes down to is that any solid that burns will make an excellent fuel when turned into dust.

Making medical equipment is hazardous, too. IV bags, tubing, hypodermic syringes, and rubber parts for them—all can be turned to dust as part of the manufacturing process, as discovered in 2003 by the North Carolina West Pharmaceutical Plant. That incident resulted in 6 deaths and 36 additional injuries, destroying the plant, and eliminating hundreds of jobs for workers in Kinston, North Carolina.

Dust Explosion Prevention

Reducing the risk of Dust Explosions all comes down to the Three C’s:

Contain, Capture, and Clean

If the combustible dust is contained and managed properly, problems don’t get a chance to evolve and reach risky levels. Sometimes a process doesn’t allow you to entirely contain the dust you generate, so instead it falls to capturing it before it disperses. Techniques can be as simple as a vacuum system for a cutting or grinding machine.

Housekeeping & Cleanliness Practices

Sometimes it is necessary to expose a product (e.g. sugar or flour) to heat and air to eliminate moisture, resulting in escaping combustible dust. That can rise up and settle on crossbeams of the roof, under conveyor belts, and piled up in corners near access doors. That must be cleaned-up, not with an air-gun, which will launch and disperse it further, but with mechanical collection or vacuums.

Some dusts are relatively harmless, like noninflammable talc or baking soda, both of which are often used in fire suppression equipment. To know your risk, collect samples of your typical dusts, and send them to a lab for dust explosion testing. Such labs can provide very specific information on the required density that will pose slight-to-extreme hazards so you can mitigate risks accordingly.

Ventilation and Dust Accumulation in Hazardous Areas

When discussing Dust Safety, getting dust away from sources of ignition is essential, but the equipment itself must be maintained. Dust accumulating inside the collection system can be an invisible hazard. When all parts of the plant are connected to a vacuum system, it needs to be equipped with explosion resistant auto-closing, over-pressure doors so explosions cannot migrate around the factory. These systems are equipped with vents to the outside so the conflagrations have a safe exit away from employees, equipment, and sources of fuel.

Hollywood Explosions – Dust As Fuel

To further illustrate how powerful dust explosions are, consider the following. On-screen explosions in movies, such as cars, tanks, buildings, and so on, are virtually never fuelled by what you see. It may look like a car gas tank going boom, but what it really is, is just a box of flammable powder, generally a type of fungus spores and a bit of nitrocellulose, being shot out of an air-cannon through a spark generator.

That is how they generate that giant fountain of flame which looks so spectacular. And spectacle is the reason they do it, plus the fact that it is extremely safe in the hands of a professional FX technician. It goes FLASH and stops almost instantly with no dangerous leftovers. Now, because it is fairly quiet, they can add “boom” sounds, put a couple of dirty acetylene burners around the “blown-up” car for orange flames, shake the camera a bit in post-processing, as it records a large box of small parts being dumped from above, out-of-frame to land nearby in a threatening manner.

Famous Dust Explosions

In 1921, an Australian coal mine explosion, powered by coal dust, blew these massive cable drums 15 metres into the air. This, despite being anchored in concrete foundations!

There have been innumerable instance of dust explosions, dating all the way back to 1785 when and Italian flour mill experienced a dust explosion that hurt two workers. Giacomelli’s Bakery Warehouse experienced said explosion, likely due to an oil lamp igniting the combustible dust.

The infamous Washburn Mill explosion killed 18 people in 1878, shown in this Library of Congress stereogram image. Pieces of the concrete roof landed quite a distance away, windows were blown out of houses and two adjacent Mills were severely damaged.

The 1893 dust explosion in Litchfield, Illinois killed one, destroyed 40 homes, and demolished businesses for two blocks around the site. The sheer level of destruction led to the first regulations for fire suppression systems in mills, and required proper training for people working in those environments.

The list goes on and on, with 23 people killed in the Quaker Oats factory in 1916; 42 in a corn dust explosion in Pekin, Illinois; 18 in a Brach’s candy factory in 1948; a grain dust explosion in 1975 which killed only two workers, but blew out windows up to 20 blocks away; and the 1977 flour dust explosion that killed 36 in Westwego, Louisiana.

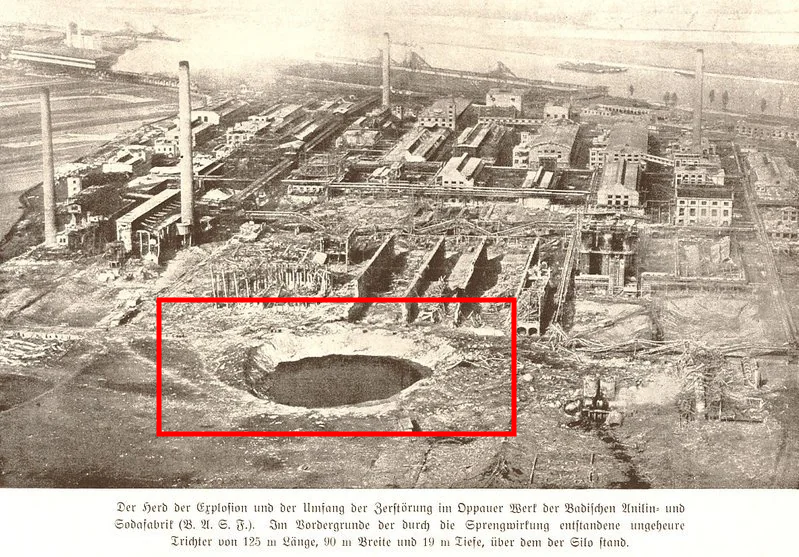

The record holder may be the 1921 chemical dust explosion in Oppau, Germany, when silos containing fertiliser ignited. The explosion killed up to 600 people directly, and injured as many as 2,000 more.

Closing Thoughts

We hope that after reading this article, it has become clear how dangerous and deceptive dust explosions can be. Hazardous substances are not always conspicuous, and dust explosions are often more destructive than gas explosions.

Disasters can be prevented through proper housekeeping and the use of explosion-proof equipment. If you have any questions about ATEX or dust explosions, we are here to help.