Definition and Principle

An Ex nR or restrictive breathing enclosure removes the fuel element of an explosion by stopping any flammable gases from entering the internal enclosure. This prevents potentially explosive gases from coming into contact with hot surfaces or ignition sources inside the enclosure.

The technique ensures the cumulative concentration within the enclosure does not exceed the lower explosive limit for the gas or vapor concentration over short and long periods of time.

Certification and Application

Restrictive breathing enclosures are certified for Zone 2 hazardous areas, where flammable gases are only present in fault conditions or during short periods of time.

Unlike Ex d enclosures, which allow for all three components required to create an explosion (oxygen, fuel, and ignition source), Ex nR enclosures remove the fuel by creating an airtight seal.

Characteristics of Ex nR Enclosures

Ex nR enclosures typically have the following characteristics:

- Lightweight metallic (e.g., aluminum) or non-metallic (e.g., GRP) construction

- Designed to prevent flammable gases from entering

- High ingress protection levels

- Tightly sealed

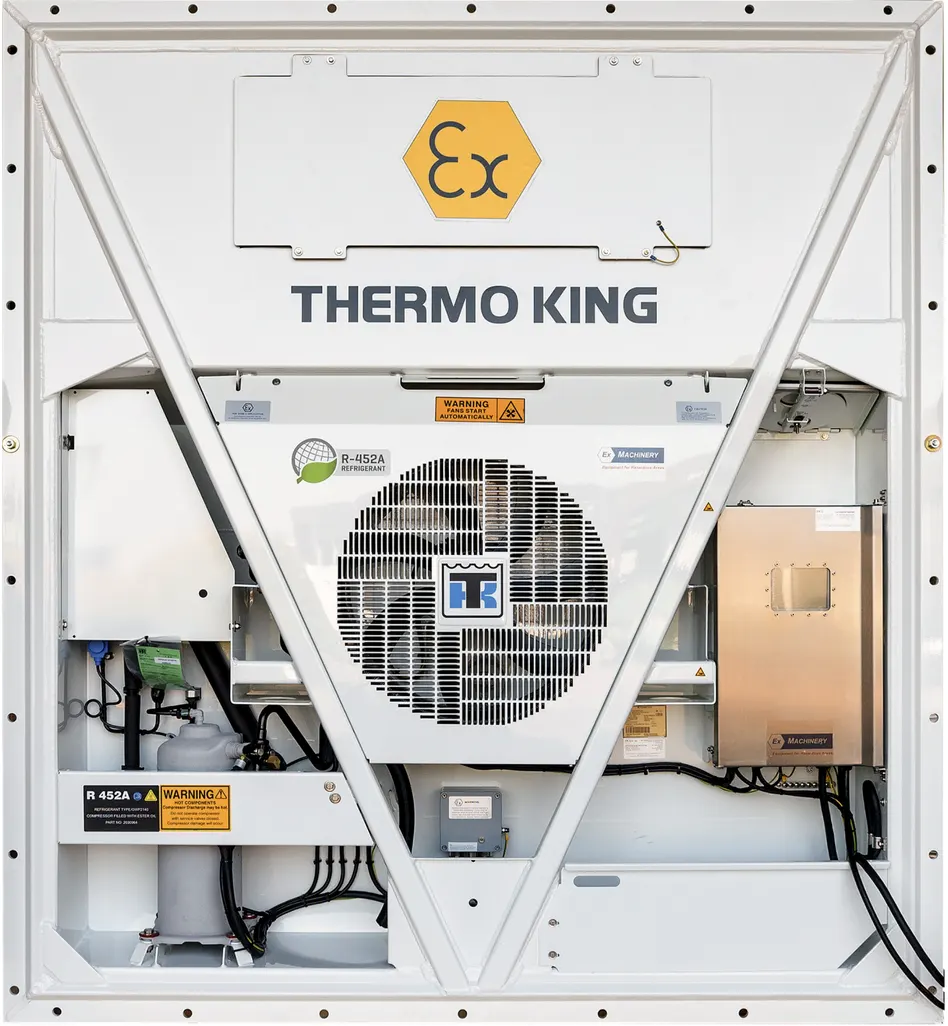

In the bottom section we see an Ex nR control box, used in the Ex Reefer unit by Ex-Machinery.

Standards and Testing

Ex nR enclosures must meet IEC 60079-15 standards for restrictive breathing. They undergo temperature rise tests and ingress testing to determine the amount of gas present inside the enclosure.

Periodic pressure test measurements are required as per EN 60079-17:2014. An enclosure is deemed restrictive breathing if it sufficiently restricts air flow both in and out.

Cable Gland Connections

The Ex nR enclosure cable gland interface requires special consideration. All glands must be suitable and certified to the Ex nR protection concept as per IEC 60079-0, Ex e and Ex d cable glands are also allowed to be used as per IEC60079-14:2014, but additional measures need to be taken to ensure a proper seal as per clause 10.8.

Ex n cable glands must meet minimum requirements including thermal endurance testing and cable pull out resistance. Special testing under IEC 60079-15 for cable and cable entry is required to ensure the inner seal is airtight in two directions.

Design Parameters

Key design parameters for Ex nR enclosures are stringent. Power loss in enclosures with sparking components must lead to an outside surface temperature increase of no more than 20 K compared to ambient temperature.

The equipment must allow monitoring of gas and vapor tightness from factory, after installation, and after maintenance. Elastomeric seals must maintain sealing properties over the equipment’s service life, while cast seals must permit a continuous operating temperature (COT) at least 10 K higher than the maximum service temperature.

Typical Applications

Ex nR is commonly used for:

- Switchgear,

- Measuring and monitoring instrumentation

- Information equipment (electrical)

- Luminaires (electrical)

A practical example of a Zone 2 Ex nR device is the Flir CX5 ATEX Thermal Camera. Its test port is located on the right side, as visible in the product image. This ATEX-certified thermal camera is available for purchase in our store.

Conclusion

Ex nR protection offers a reliable method for safeguarding equipment in Zone 2 hazardous areas. Its main advantages include lightweight construction, cost-effectiveness compared to Ex d enclosures, and suitability for a wide range of electrical equipment.

However, Ex nR also has limitations. It’s restricted to Zone 2 areas only, requires regular testing to ensure seal integrity, and may not be suitable for equipment that generates significant internal pressure. Despite these constraints, Ex nR remains a valuable tool in the arsenal of explosion protection techniques, providing a balance between safety and practicality in less severe hazardous environments.